BACK TO HOME

Cornell Corner

Shrinking the taphole, does it impact production?

Adam Wild, Director Cornell University Uihlein Maple Research Forest | December 13, 2023

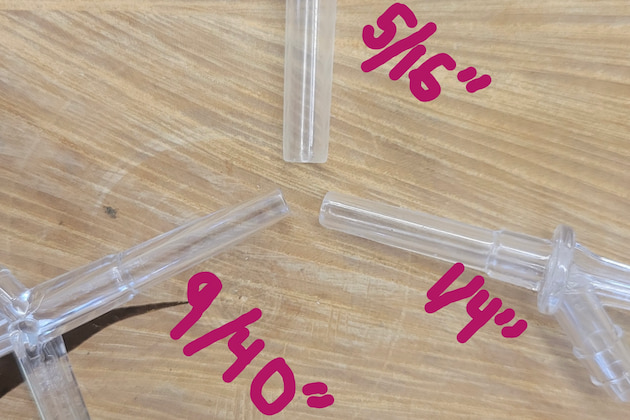

LAKE PLACID, N.Y.—For the past couple decades, 5/16-inch diameter tap holes have been the commercial maple industry standard since switching from 7/16 inch spouts.

Over the years, folks have experimented with even smaller diameter tap holes with mixed results.

More detailed research has shown that ¼ inch diameter tapholes yield 10% less than a 5/16 inch diameter tapholes (3rd Ed. North American Maple Syrup Producers Manuel) while many equipment catalogs and producers claim they get the same yield from ¼ inch diameter spouts or smaller.

So how do smaller diameter spouts perform? Having a smaller diameter spout has the potential of creating narrower compartmentalized wounds within a tree. This is beneficial for trees that have been tapped for many decades and trees located in marginal soils or short growing seasons.

During the maple season of 2022 and 2023 we tested the sap yield from 5/16 (0.3125) inch diameter tap holes, 1/4 (0.25) diameter tapholes and 9/40 (0.225) diameter tap holes at the Cornell University Uihlein Maple Research Forest in Lake Placid, NY.

[ MORE ]

New products from Cornell: Maple lip balm and more

Ailis Clyne, Cornell Maple Program | December 13, 2023

VAN ETTEN, N.Y.—Maple is an enticing ingredient in so many products, and its usefulness can apply to more than just foods.

Honey is already utilized by producers and cosmetics manufacturers alike in numerous skin care and bath products ranging from hand-crafted cold process soaps to high-end face masks.

Maple is similarly well-suited to many of these products, and even has an advantage over honey: the relative ease of being made into a granulated sugar, which opens up a world of products that are easy to make and market.

What benefits does maple lend to skin care products?

Skin-loving components include: trace minerals, amino acids, phenolic compounds, vitamins, antioxidants, and of course, sugar which can act as a humectant (moisturizing) and an exfoliant.

[ MORE ]

Cornell touts new maple marshmallows recipes

Catherine Belisle, Ph.D. and Ailis Clyne | January 6, 2023

Quarter inch tubing showing promising early results

Adam Donald Wild | May 11, 2022

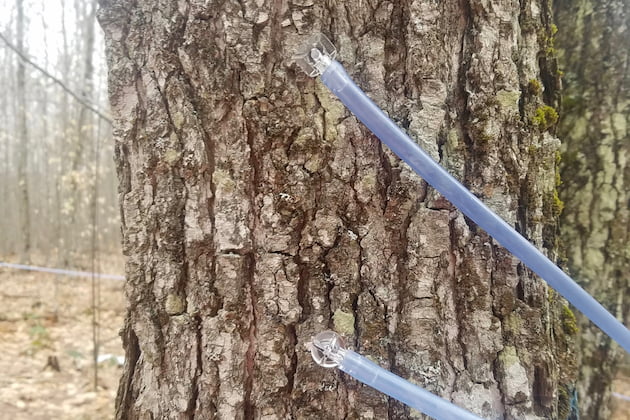

LAKE PLACID, N.Y.—Quarter inch tubing is showing promising early results in our latest research, getting high vacuum on gravity and potentially less likely to plug than 3/16ths tubing.

The use of 3/16” diameter tubing still remains a great option in gravity sap collection systems where the smaller inner diameter of 3/16” tubing allows a full column of sap to form through capillary action.

When the weight of the full column of sap drops in elevation, natural vacuum is achieved if the tubing is airtight.

When applied in a natural gravity system, under appropriate topographical conditions, 3/16” tubing can achieve maximum potential vacuum (often better than a vacuum pump) and even has capabilities to pull sap up and over a hill.

This maximum yield is achieved without the need for high priced vacuum pumps, energy input to run a pump, and 3/16” diameter tubing is cheaper to install.

However, recent research shows that sap production in 3/16” tubing drops off as soon as the second year after installation due to microbial growth. [ MORE ]

Cornell's Aaron Wightman to give free seminar at Hoover Maple in Branchport, N.Y.

Peter Gregg | December 9, 2021

BRANCHPORT, N.Y.—Cornell Maple Program director Aaron Wightman will be giving a free seminar at Hoover Maple Supplies on Friday.

Wightman will begin his talks at 10:00 a.m. and will cover the following:

—gypsy moths and how to manage your sugarbush for resilience against forest pests

—tubing sanitation and maintaining production in 3/16" lines

—tips for top quality, high flavor syrup

—new product development [ MORE ]

Cornell opens new state-of-the-art maple facility

Peter Gregg | August 12, 2021

VAN ETTEN, N.Y.—The doors are open on a new state-of-the-art maple research facility for the Cornell Maple Program.

The New York State Department of Agriculture and Markets and Cornell University’s College of Agriculture and Life Sciences (CALS) last month held a grand opening of the newly rebuilt Arnot Maple Research and Teaching Laboratory, which will house the first-of-its-kind new maple product development lab in the country.

Funded through $500,000 from the state budget, the laboratory is expected to foster further growth and innovation in New York’s maple industry.

The brand new 4,200-square-foot facility includes a new commercial kitchen and increased capacity for research and development of new maple products.

“Cornell’s Arnot Maple Research and Teaching facility conducts groundbreaking research that is critical to the growth of our state’s maple industry, which contributes significantly to the state’s ag economy,” said state agriculture commissioner Richard Ball. [ MORE ]

5/16 vs. 3/16 no clear winner

Paul Post | May 26, 2021

SHREWSBURY, Vt.—There’s a great deal of debate and no clear consensus among sugarmakers about the benefits of 5/16-inch versus 3/16-inch tubing.

One sure thing with either system is it's absolutely essential to keep tapholes free of bacteria and yeast, which build up and reduce sap flow, resulting in lost production and revenue.

In a recent webinar, New York State Maple Specialist and Cornell Maple Program Director Aaron Wightman outlined extensive sanitation research for both types of tubing to help producers enjoy the full rewards of all their hard work and effort.

He was joined by sugarmaker Arthur Krueger of Krueger-Norton Sugarhouse in Shrewsbury, Vt. and a noted 3/16 tubing pioneer.

The trials Wightman described were conducted at Cornell’s two 7,500-tap research sugarbushes at the Arnot Forest near Ithaca, N.Y. and at Uihlein Center in Lake Placid, N.Y.

“We aren’t just doing our research in a Petri dish,” Wightman said. “A lot of these treatments we’ve tried on thousands of trees. These aren't hypothetical research concepts. We’ve actually tried them on a large-scale, commercial setting. So we have that experience to back up the evidence.” [ MORE ]

Maximum sap 101

Paul Post | February 10, 2021

LAKE PLACID, N.Y.—More taps doesn’t necessarily mean more sap.

Some factors such as climate, elevation, tree health and size, and surrounding species composition are beyond a sugarmaker’s control.

But understanding how they impact production, and learning how to work with them, can prove quite beneficial.

This plus adhering to good tapping practices and having a well-designed system is the perfect recipe for a smooth-running, efficient and profitable operation, said Adam Wild, director of Cornell University’s Uihlein Maple Research Center in Lake Placid, N.Y. during a maple seminar last month.

Wild’s webinar, “Maximizing Production in Your Sap Collection System” was the sixth and final segment of an online introductory course for new and beginning sugarmakers.

However, the session had valuable reminders for veteran maple producers as well.

“Not every sugarbush has equal production potential,” Wild said. “If you’re not producing as much as you think you can I’m sure there’s lots of room to increase production. This is going to differ from region to region, state to state, but also can change locally.”

[ MORE ]

Making bucks from the buddy

Aaron Wightman | January 7, 2021

VAN ETTEN, N.Y.—Does buddy syrup have potential high-value uses?

That is the subject of a new research project at Cornell University, where maple specialists are investigating a wide range of value-added options for this much maligned, late-season flavor.

Maple trees enter a period of dormancy at the end of each growing season.

This is an adaptation that allows trees to survive the cold of winter. An important aspect of that survival strategy is the management of energy reserves in the form of sugars and starches. [ MORE ]

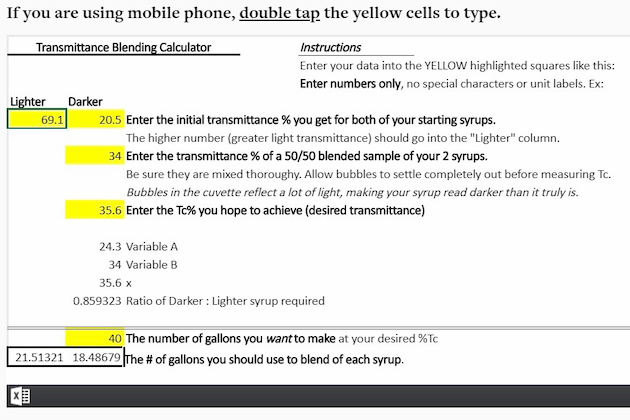

Grade Blending – a new calculator to get your syrup in grade

Ailis Clyne Technician, Cornell Maple Program Cornell University, Department of Natural Resources | October 7, 2020

VAN ETTEN, N.Y.—Have you ever wanted to blend two syrups of different grades to meet your customers’ needs?

The Cornell Maple Program has developed a new user friendly tool to calculate how many gallons of each syrup you would need to blend.

This calculator will only help those of you using digital light meters that give you the percentage of light transmittance (%Tc) through your syrup.

It won’t help if you use a visual kit.

[ MORE ]

Beech syrup can add value to your operation out of pesky trees

Adam Donald Wild | September 14, 2020

LAKE PLACID, N.Y.—Love ‘em don’t hate ‘em.

You know those pesky beech trees growing so thick in your sugarbush it makes it hard to walk through and when you do, they slap you in the face? Well, we are tapping those beech trees for syrup production.

Yes, you read correctly, we are tapping American beech (Fagus grandifolia) trees at Cornell University’s Uihlein Maple Research Forest in Lake Placid, NY. Since the infestation of beech bark disease throughout northern forests beech trees have been rendered to little economical value besides firewood.

By tapping the trees for sap collection, it may be possible to create value from the beech trees in your forest.

[ MORE ]

Get Brewing with Maple Beer

Aaron Wightman, Cornell Maple Program Extension Associate | August 17, 2020

VAN ETTEN, N.Y.—How ‘bout a cold one?

As maple production continues to increase, product diversification becomes an increasingly important strategy for maintaining industry profits.

Craft beers that feature maple syrup as a prominent ingredient represent a large potential market opportunity.

The Cornell Maple Program is working with brewing experts to create guidance for the best use of maple in making high quality beers.

Brewing beer with maple syrup or sap is not a new practice. Many hobbyists and even a few commercial scale breweries have produced beers with a maple component for years.

However, with the continued growth of the craft brewing industry, the beer industry may hold untapped opportunities for sugarmakers.

[ MORE ]

Bleaching and double-tapping part of maple tubing trials on 5/16 lines from Cornell

Steve Childs, New York State Maple Specialist | July 13, 2020

VAN ETTEN, N.Y.—During the 2020 maple season five treatments were tested on 5/16 lines at the Arnot Forest Research Forest.

Each treatment was repeated 4 times in the Arnot Forest sugar bush and each of these replications had four taps on a single lateral line.

The first sap runs were recorded on February 1 and the last reading was recorded on March 30.

The treatment used as a check used old spouts and drops where the drop has been used for 8 years and the spout has been in use for 5 years.

Lines had been vacuumed dry at the end of previous seasons when the taps were pulled but received no other cleaning.

The second check for standard comparison is new drops and spouts while the lateral lines were not replaced.

This year the old system yielded 26.1 gallons of sap per tap while the all new spouts and drop system yielded 40.7 gallons of sap per tap representing an increase of 14.6 more gallons of sap per tap. [ MORE ]

Double-tapping trees might yield results, say Cornell researchers

Kara Lynn Dunn, Northern NY Agricultural Development Program | June 15, 2020

LAKE PLACID, N.Y.—Retapping trees could result in 20 percent more sap.

“Recent projects that looked at the optimum time for tapping maple trees indicated that early tapping to capture early season sap runs and re-tapping later in the season could have potential to increase syrup production yields by at least 20 percent or a $6 per tap profit increase,” said Adam D. Wild, director of Cornell University’s Uihlein Maple Research Center.

This season Wild is conducting trials to test the feasibility of re-tapping maple trees during the sap season. His research is funded by the farmer-driven Northern New York Agricultural Development Program (NNYADP), which is helping regional maple producers evaluate and add opportunities to increase sap and syrup production.

Sugarmakers shouldn’t rush out to re-drill trees just yet. Wild said the feasibility of the method needs more data, which he hopes to collect and publish this spring.

[ MORE ]

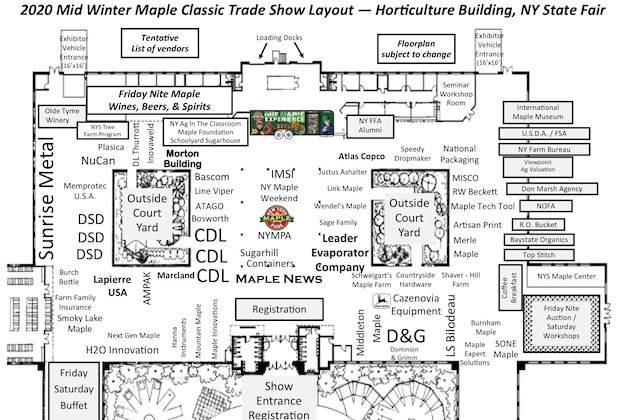

Mid-Winter Classic Maple Show this weekend

Peter Gregg | January 2, 2020

SYRACUSE, N.Y.—This year’s Mid-Winter Maple Classic will take place on tomorrow and Saturday, January 3 and 4 at the New York State Fairgrounds in Syracuse. It's the biggest maple trade show of the year and typically draws more than 1,000 sugarmakers, venders and educators.

This is the second year the conference will be held at this location which offers a large space to fit the entire trade show, and meeting rooms that can accommodate larger audiences.

The day-and-a-half event will be hosted by the New York Maple Producers Association in conjunction with the New York FFA Alumni Association and Cornell Maple Program. The conference will follow a similar format as previous years.

[ MORE ]

It could be the T's

Stephen Childs, NYS Maple Specialist | November 7, 2019

ITHACA, N.Y.—The results of tests conducted in the 2019 sap season at the Cornell Arnot Forest has clarified one important question: Why do we experience yield loss with 3/16th tubing after the first year?

This was the fourth season where experiments were run using 3/16 tubing with true 3/16 fittings and Ts.

A variety of different combinations of spouts, drops and cleaning methods were tested, but in each case the age of the T was the primary yield controlling factor while the method of tap hole sanitation used in the test was secondary. [ MORE ]

Maple kombucha could be a next big thing

Ailis Clyne, Cornell Maple Program | September 6, 2019

VAN ETTEN, N.Y.—Kombucha is the new health beverage craze that is sweeping the nation, and the newest value-added opportunity for maple producers.

Market research suggests a growth rate of 23 percent reaching a market worth of up to $5.45 billion by 2025.

Yet, no big players are brewing with maple.

Kombucha is so new on the scene that much of its growth is attributed to the development of new flavors.

At the Arnot Research Forest, part of the Cornell Maple Program at Cornell University, we have experimented with and fine-tuned a process for brewing kombucha with maple syrup and the results have gotten overwhelmingly positive reviews.

Kombucha is a refreshing, bubbly drink made by fermenting sweet tea. [ MORE ]

Making maple wine can be a new way to profits

Aaron Wightman, Cornell Maple Program Extension Associate | August 13, 2019

VAN ETTEN, N.Y.—Maple syrup can be diluted and fermented to create a pleasant, full-bodied wine with elegant structure and great maple character.

However, without proper materials and technique, it is easy to make a poor quality wine that is bitter, astringent or sickly sweet.

This winter, the Cornell Maple Program worked with undergraduates at Cornell University to create guidelines for high-quality maple wine production.

Traditional wines are created through the fermentation of grape juice sugars by specialized yeasts. This ancient industry has seen a surge in growth in recent decades.

The New York State wine industry alone now generates over $4.5 billion in annual economic activity. An increased interest in domestic wines creates an opportunity for non-traditional wines produced with alternative sugars.

With maple wine, maple producers can tap this lucrative and expanding market. [ MORE ]

Get it bubbling

Aaron Wightman, Cornell Maple Program Extension Associate | July 7, 2019

VAN ETTEN, N.Y.—Dissolved oxygen levels have a significant impact on syrup grade and flavor, especially in late-season sap.

This season, we found that boosting oxygen levels in sap with a bubbler makes darker syrup with a stronger maple flavor.

In late season saps, the flavor improvement due to bubbler-aeration was significant enough to improve an off-flavored syrup to a dark, table-grade syrup.

Many factors affect the grade and flavor of maple syrup.

One of the lesser known variables impacting syrup quality is the level of dissolved oxygen in sap. [ MORE ]

Does taphole sanitation pay off?

Stephen Childs and Aaron Wightman, Cornell Maple Program | July 8, 2019

ITHACA, N.Y.—Does extra attention to your tubing and taphole sanitation pay off?

During the 2019 maple season the Cornell Maple Program conducted a number of trials on 5/16 tubing looking at a variety of tubing options for taphole sanitation and tapping.

This year the first sap yield measurements were taken on February 8 and the last measurements on April 10.

We compared several new variations to our set-up of old spouts and drops where the dropline has been used for 7 years and the spout has been in use for 4 years. They have been vacuumed dry at the end of each season when the taps are pulled but receive no other cleaning.

The second check for standard comparison is completely new laterals, drops and spouts for a completely new system. [ MORE ]

Maple beverages offer another revenue stream

Deborah Jeanne Sergeant | May 8, 2019

SYRACUSE, N.Y.—Keith Otto is taking value-added maple in directions few sugarmakers have taken it.

Things like maple beer, wine, spirits, cider and kombucha.

"There's great potential for adding value to your existing business," Otto said during a presenation at the Mid-Winter Classic Maple Show in Syracuse last January.

Otto is a researcher with the Cornell Maple Program and the Uihlein Maple Research Forest in Lake Placid, N.Y.

There's untapped potential--literally--in New York's forests, he said. [ MORE ]

Are foil packs worth it?

Peter Gregg | May 1, 2019

SYRACUSE, N.Y.—As packaging technology advances, there may be new ways to make money in maple. But how about with foil packs?

Foil packs are available for bulk purchase online in several different sizes. Some maple companies have been able to mass produce the packets and market them to the running and fitness demographic as single serve “one shot” energy boosters for athletes.

But Steve Childs of the Cornell University Maple Program set out to find if there is any profit in selling single serve foil packs for the average sugarmaker.

“We wanted to find the ‘farmer’ way of doing it,” Childs said, during a standing-room only seminar at the Mid-Winter Maple Classic in Syracuse on Jan 5.

“Is there any way to fill these ourselves in any sort of practical way,” Childs said. [ MORE ]

Cornell study shows results from re-tapping holes

Stephen Childs and Aaron Wightman, Cornell Maple Program | December 4, 2018

In the 2018 Cornell Maple Program replicated tubing system sap flow trials, one of the first systems to stop running was the second year 5/16” laterals, drops and spouts with four replications.

In this treatment nothing had been changed since its use in the 2017 sap season other than being vacuumed dry at the end of the 2017 sap season. By April 6 they had completely dried up. On April 6, a new tap hole was drilled 6 to 8 inches directly above or below the original 2018 taphole.

This taphole location was chosen so as not to create a new partition zone in the tree thereby saving clean white wood for future tapping. It was also located in the same channel to see if there would be significant air leakage across the 6 to 8 inches.

[ MORE ]

Tap hole sanitation research in the ’17 season

Stephen Childs and Aaron Wightman, Cornell Maple Program | Feb. 28, 2018

In 2017, 11 replicated maple tubing research plots were established at the Arnot Forest to provide information useful in identifying which methods of reducing microbial contamination of the tap hole are most effective and result in increased sap production. [ MORE ]

Working with little ROs for syrup production

Stephen Childs, New York State Maple Specialist | Oct. 12, 2017

One of the biggest drawbacks of making maple syrup for a back yarder or small maple producer is the time it takes to boil the sap into syrup. The idea of using a small reverse osmosis unit to assist with the syrup making is very interesting to many small maple producers.

There are many little reverse osmosis systems available for water purification in households or for small commercial applications. These can be purchased from a number of big box stores, home improvement stores or on line. These RO units can be used to remove water from sap to speed up the concentration and syrup boiling process. [ MORE ]

3/16” tubing results from Uihlein Forest

Michael Farrell | February 2017

There has been a lot of interest in 3/16” tubing systems over the past several years. Tim Wilmot’s research on this novel concept has caused a lot of producers to rethink how they install new tubing systems or potentially renovate their existing sugarbushes. Despite a lot of in-depth research reports and successful stories from sugarmakers who have used 3/16” systems, there still remains a lot of skepticism and questions among producers who are reluctant to switch away from 5/16” systems. It should be obvious that using 3/16” will always be better in a gravity based system, yet the answer when using vacuum pumps does not have a solid consensus. In 2016, we received funding from the Northern NY Agricultural Development Program to conduct research and extension on using 3/16” tubing systems under vacuum. This article describes our research results from the past year and outlines future directions.

[ MORE ]

Importance of focusing on syrup quality

Michael Farrell | Feb. 2016

I have been attending the board meetings of the International Maple Syrup Institute for the past several years. The agendas are always interesting and focus on a wide variety of topics of importance to the maple syrup industry, including many facets of marketing and promotion, misrepresentation of maple syrup in the marketplace, and ensuring product quality.

[ MORE ]

Research Update on Birch Sap & Syrup Trials

Michael Farrell | Jan. 2016

For the past several years we have been conducting research and extension on tapping birch trees for their sap and syrup production. This article presents some of the lessons learned to date and presents some basic answers to some of the most frequently asked questions with tapping birch trees, to the best of our current knowledge.

[ MORE ]

Planning for a sustainable future for U.S. maple

Michael Farrell | November 2015

The past ten years been a tremendous time for the entire maple industry. We have seen massive expansion in taps and the yields per tap have been steadily rising. Markets for syrup have been growing and prices have been relatively high and stable. However, we must also realize that much of our growth has come about due to wise investments made in the past. [ MORE ]

First international birch conference a success

Michael Farrell |

This past June nearly 70 current and potential birch sap and syrup producers from all over the world got together for 3 days at Paul Smiths College in the heart of the Adirondacks to network and share information. There were plenty of existing maple sugarmakers from the northeast who are already producing birch syrup or thinking of doing so along with birch sap and syrup producers from Alaska, nearly every Canadian province, eastern Europe and Russia. [ MORE ]

Some strategies to control American beech

Peter Smallidge |

American beech and many other native and non-native woody plants can dominate a woodland, exclude or limit the regeneration of desired plant species, and limit the biodiversity of the site. In high abundance, these species can complicate access for maple producers. Often these interfering species gain dominance because of selective deer browsing of desired plant species, and prolonged deer pressure can create a legacy effect that persists even if deer impacts are controlled.

[ MORE ]

Update on Cornell tests on 3/16” maple tubing

By Stephen Childs NYS Maple Specialist |

During the 2014 maple season the Cornell Maple Program conducted three demonstration sites using 3/16” maple tubing. Each demonstration site was set up in the month of February and tapped the last week of February. The first sap run occurred on March 10th. The demonstrations were set up to compare sap yield from a new 5/16” lateral line with 8 taps using 5/16” standard black check valve spouts on new 5/16” drop lines with sap yield from a new 3/16” lateral line with 8 taps using 5/16” standard black check valve spouts on a new 5/16” drop lines for 8 inches then fitted to 3/16” drop line.

[ MORE ]

How joint marketing can help the maple industry

Michael Farrell |

At the most recent meeting of the International Maple Syrup Institute and North American Maple Syrup Council in Nova Scotia, the IMSI brought in Ellen LaNicca to speak about joint marketing efforts in the agricultural sector. [ MORE ]

Highlights from 2014 Natural Products EXPO East

By Michael L. Farrell |

This September I had the fortunate opportunity to attend Natural Products EXPO East, one of the largest trade shows in the country focused on natural foods and related items. [ MORE ]

Factors that influence crystal size in maple products

Stephen Childs |

A very important factor in making quality maple value added products is to size sugar crystals so the product feels great to the customers’ mouth. For some products such as maple candy and maple cream a very smooth mouth feel is preferred by most customers. If making maple granulated maple sugar a grainier texture is preferred. Unfortunately it is much easier to make grainy textured creams and candies than smooth textured due to the extra attention required to make sure a smooth texture is accomplished. [ MORE ]

Weighing pros, cons of producing birch syrup

Michael Farrell |

Although many sugarmakers have heard that you can tap birch trees, very few of us have actually tried to produce birch syrup, and folks who have boiled down some birch sap have mostly had negative experiences. The sugar content of birch is much lower than maple sap (usually between .5-1 brix), so it takes a very long time to boil it down, especially when it’s done on a small scale without efficient processing technologies. [ MORE ]

Determining the value of sap you produce

Michael Farrell |

In the previous issue of The Maple News, I submitted an article summarizing the research carried out by the Parker Family Maple Farm comparing the differences in their yields and profitability when utilizing different combinations of spouts and droplines.

[ MORE ]

Limiting conservative tapping guidelines

Brian Chabot, Cornell Maple Program |

The article by Abby Van Den Berg et al (Maple News November 2013) provides valuable research support for understanding the key variables behind tapping guidelines. Prior to 2005 there was no research supporting any of the guidelines in use. However, maple producers need to pay careful attention to the caveats mentioned in the article [ MORE ]

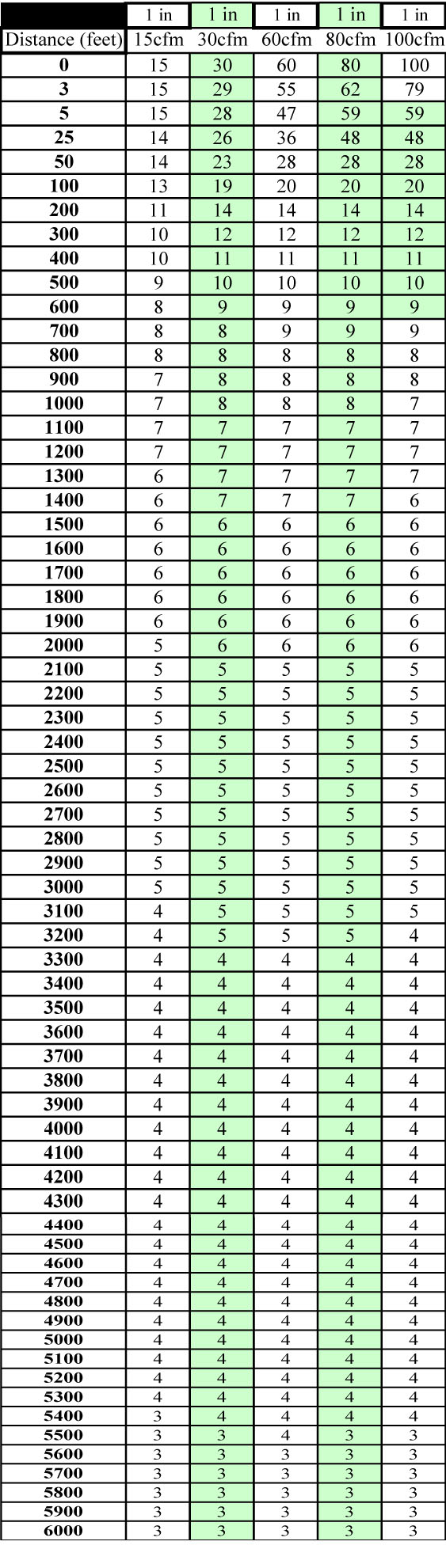

Mainline sizing guidelines and worksheets for 1” line

Stephen Childs, NYS Maple Specialist |

The number of taps that can be properly supported on a one inch mainline depends on a number of factors including the line loss due to friction in the line, the length of the line, the slope of the line, sap volume in the line and vacuum capacity available to the line. [ MORE ]

Some ideas for maple marshmallow products

Stephen Childs, New York State Maple Specialist |

Maple marshmallow can be served in a variety of formats. One favorite is to make rice crispy treats using the freshly made maple marshmallow in place of melted regular marshmallow. [ MORE ]

Estimating taps per acre using the angle gauge

Stephen Childs, Cornell University |

Maple producers may wish to estimate the potential number of taps per acre to assess the productive capacity of an area, and to aid in estimating the costs for installing tubing systems or buckets. Once you know the number of taps per acre, you can compare sites and estimate costs using the tapping and tubing cost estimator. [ MORE ]

Which spout is best for your operation?

Brian Chabot, Steve Childs and Michael Farrell |

In the past couple of years there has been a flurry of innovation in spout design each with their own claimed advantages for cost, ease of use, and sap yields. [ MORE ]