Cornell Corner

Get Brewing with Maple Beer

Cornell Maple Program develops maple beer recipe for home brewers and market potential

By AARON WIGHTMAN, CORNELL MAPLE PROGRAM EXTENSION ASSOCIATE | AUGUST 17, 2020

VAN ETTEN, N.Y.—How ‘bout a cold one?

As maple production continues to increase, product diversification becomes an increasingly important strategy for maintaining industry profits.

Craft beers that feature maple syrup as a prominent ingredient represent a large potential market opportunity.

The Cornell Maple Program is working with brewing experts to create guidance for the best use of maple in making high quality beers.

Brewing beer with maple syrup or sap is not a new practice. Many hobbyists and even a few commercial scale breweries have produced beers with a maple component for years.

However, with the continued growth of the craft brewing industry, the beer industry may hold untapped opportunities for sugarmakers.

Recent years have seen a shift in consumer preferences away from mainstream beverage brands and toward craft beverages.

The term “craft” refers to small and independent companies. Growth in the craft beer industry has been driven by an explosion of new local breweries across the United States.

Since 2014 the number of craft breweries operating in the United States has roughly doubled from 3,814 to 8,275 by 2019, with total sales of $29.3 billion according to the Brewers Association.

Most breweries offer an evolving menu of unique beers, brewed on-site in a pub or microbrew setting. As the industry grows and competition increases, many brewers are devoting increased resources toward differentiating their products.

Often these new brews feature natural and locally produced ingredients.

Maple syrup is one such ingredient that could be used to produce a variety of ales, lagers, porters, stouts and a diversity of other craft brews. If maple-style beers gain mass appeal, the sales implications for maple producers could be considerable.

Last year craft brewers sold over 800 million gallons of suds.

If just 1% of those beers were brewed with maple added at a rate of 0.15 pounds per gallon, that would equal over 110,000 gallons of maple syrup.

One barrier to bringing quality maple beers into the mainstream is a lack of knowledge regarding the best practices for using maple syrup in brewing.

To address this concern, the Cornell Maple Program is working with university and industry experts to develop guidelines and sample recipes.

This winter, as part of that effort, the maple program paired with student researchers and the Cornell Department of Food Science to explore options for nut brown ale and amber ale brewed with maple.

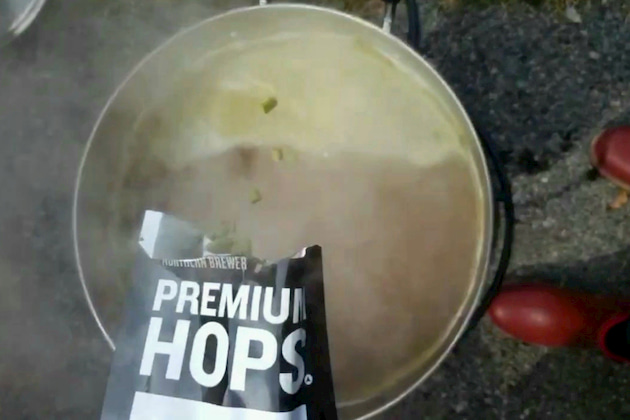

In particular, the group looked at syrup grades, addition rates, the timing of maple additions during the brew process and complimentary mash ingredients. Through 36 separate brewing trials, several key findings emerged.

First, timing is key to retaining maple flavors and aroma.

If maple syrup is added to the wort before primary fermentation, many of the volatile components that give maple its distinctive flavor are lost or consumed as the yeasts convert sugars to alcohol.

Therefore, it is critical that maple syrup additions are made after the primary fermentation is complete.

This can be done through a secondary fermentation process or by adding maple as the “priming sugar” which is the sugar added after the main fermentation in order to carbonate the beer.

The second key finding is the importance of choosing complimentary grains for the mash ingredients.

In general, the typical grains for amber ale allow maple to stand out as a predominant flavor. However, choosing the right specialty malt can greatly enhance the maple character.

For example, in our trials the specialty malt Caramel 60 helped give maple more definition.

By contrast, the dark malty flavors of a nut brown ale are complimentary to maple, but do not allow it to present as strongly. Instead the maple suggests its presence in a pleasant, light aroma when brewed in conjunction with quality specialty malts.

The use of a more robust maple source such as a very dark syrup or amorphous maple sugar may overcome this challenge to some degree, creating a detectable presence on the palate.

Lastly, we studied the potential use of fenugreek as an all-natural option to boost the appeal of maple beers.

Fenugreek is an annual plant which has a heavy maple aroma coming from a compound called sotolon.

The addition of this powdered spice was made at bottling in order to lift the aromas of other maple additions which were made.

This could be a very easy addition for producers to make in future experiments of maple beers and something that can enhance the perception of maple beers in the marketplace.

A complete report on maple beer research and other new products development information can be found at cornellmaple.com.

The Cornell Maple Program would like to acknowledge the valiant efforts of our student research team who worked from home, spread across several time zones after Cornell University closed its campus in March in response to the coronavirus pandemic.

Their tremendous dedication resulted in the highly-detailed and informative report now published on the maple program website.

The team was composed of food science seniors Blake Huber, Gwendolyn Pieper, Miranda Sannino, Marete Seymour and Allyson Wentworth.

The Cornell maple team would also like to thank our funding supporters from USDA National Institute of Food and Agriculture as well as the NY Department of Agriculture and Markets.