Cornell Corner

Quarter inch tubing showing promising early results

Alternative gravity tubing that could prevent plugging

By ADAM DONALD WILD | MAY 11, 2022

LAKE PLACID, N.Y.—Quarter inch tubing is showing promising early results in our latest research, getting high vacuum on gravity and potentially less likely to plug than 3/16ths tubing.

The use of 3/16” diameter tubing still remains a great option in gravity sap collection systems where the smaller inner diameter of 3/16” tubing allows a full column of sap to form through capillary action.

When the weight of the full column of sap drops in elevation, natural vacuum is achieved if the tubing is airtight.

When applied in a natural gravity system, under appropriate topographical conditions, 3/16” tubing can achieve maximum potential vacuum (often better than a vacuum pump) and even has capabilities to pull sap up and over a hill.

This maximum yield is achieved without the need for high priced vacuum pumps, energy input to run a pump, and 3/16” diameter tubing is cheaper to install.

However, recent research shows that sap production in 3/16” tubing drops off as soon as the second year after installation due to microbial growth.

With a small inner diameter, bacteria and yeast grow within the tubing and over time cause clogging, especially within any fittings where the inner diameter is less than 3/16” (Childs, 2019).

This plugging restricts sap flow and diminishes potential yield. Despite the initial gains from 3/16” diameter tubing, by year three of using the tubing, production diminishes to significantly less than using 5/16” tubing without vacuum unless the tubing is sanitized.

A replacement for 3/16” diameter tubing in gravity systems could be 1/4” tubing.

With almost twice the aperture of 3/16” tubing (0.049 sq inches compared to 0.0275 sq inches), 1/4" inch tubing is less likely to plug from microbes yet is still able to create a full column of sap for gravity vacuum.

Quarter inch tubing is currently not available for maple producers but can be procured from other industries and with modifications, will work for maple production.

Quarter inch tubing is not necessarily new to the maple industry but with better plastic tubing and fittings, we were able to test 1/4” tubing more effectively.

Thanks to funding from the Northern NY Agriculture Development Program, we were able to test the effectiveness of 1/4” inch tubing at the Cornell University Uihlein Maple Research Forest in Lake Placid, NY during the 2020& 2021 maple season.

Four replications were established on a slope of at least 50 feet drop in elevation.

Each replicate block contained a 3/16” lateral line, a 1/4” lateral line, and a 5/16” lateral line with the same length and elevation drop with trees matched in elevation across the three lateral lines.

Block one had 8 taps/trees per lateral, block two had 10 taps per lateral line, block three had 18 taps per lateral line, and block four had 30 taps per lateral line.

Each lateral line flowed into its own tank where sap volume could be measured.

All lines were on gravity without the use of a vacuum pump.

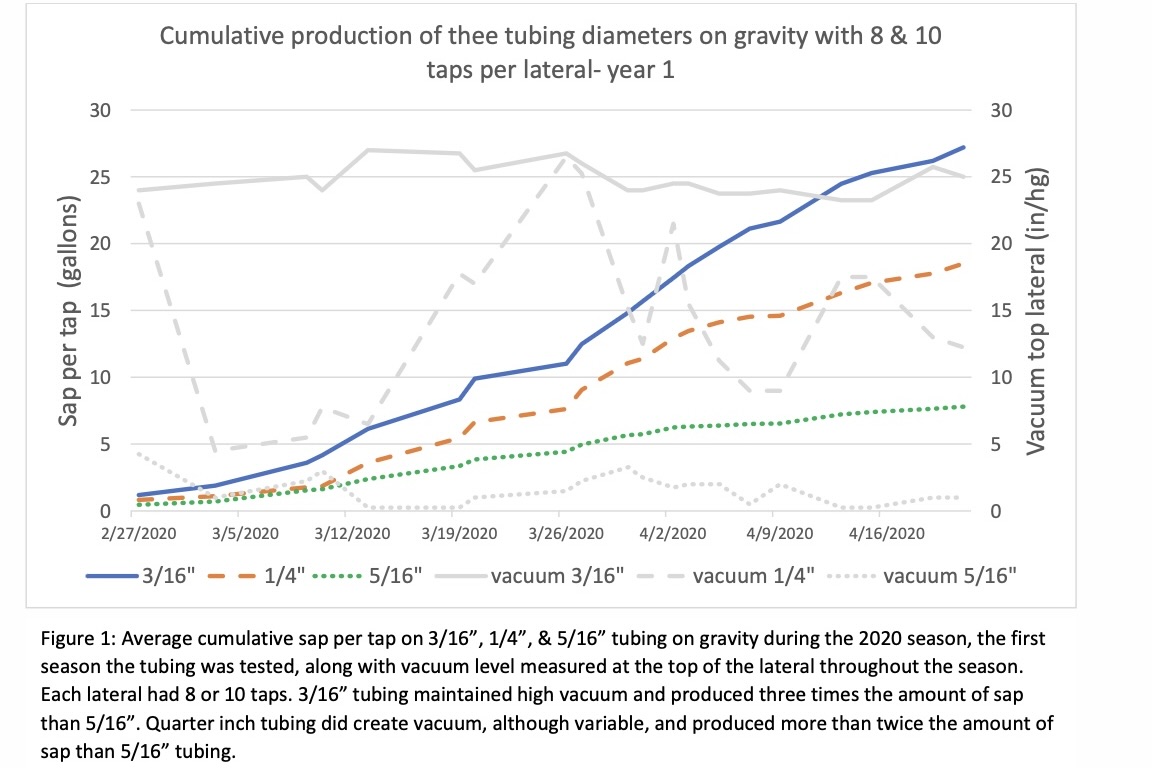

In the first year of testing with just 8 and 10 taps per lateral, 3/16” tubing achieved consistently high vacuum at the top of the lateral and produced over three times the amount of sap per tap than 5/16” tubing (figure 1).

Quarter inch tubing did achieve vacuum at the top of the lateral (as high as 25 in/hg) but the vacuum was not consistent throughout the season, yet still produced more than twice the amount of sap per tap than 5/16” tubing (figure 1).

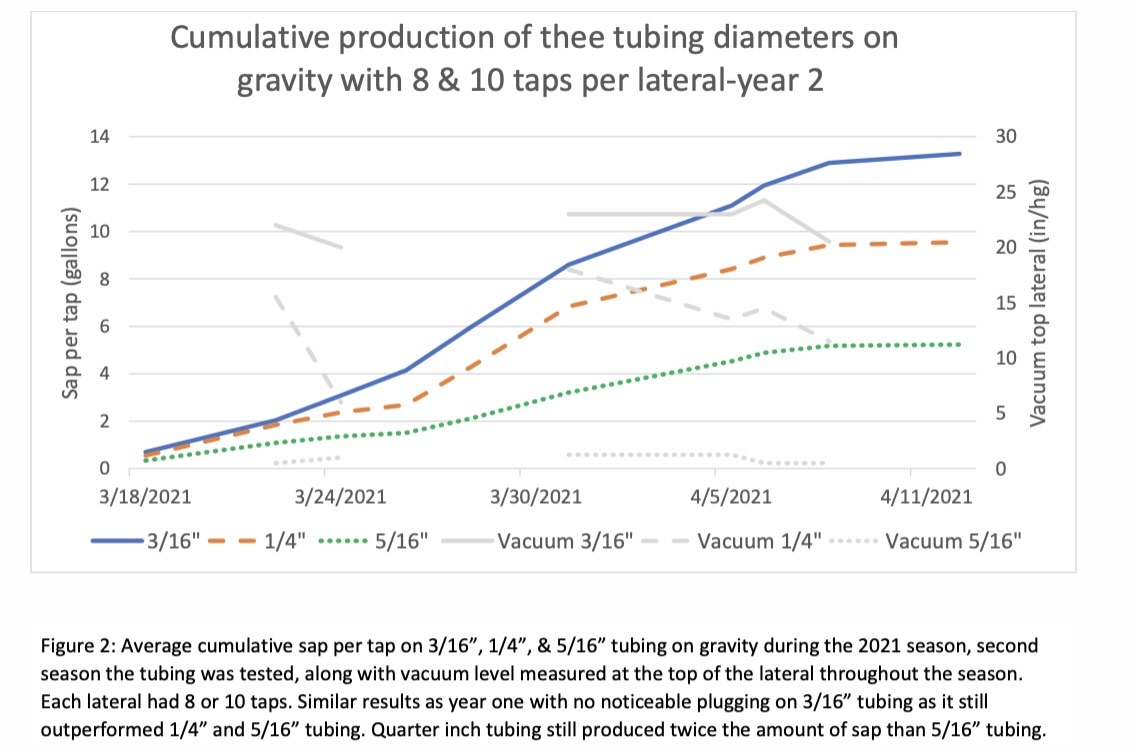

The 5/16” tubing produced little to no vacuum at the top of the lateral line. In second season spouts were replaced but droplines and laterals were not cleaned. Similar results were observed during the second season with no significant plugging on 3/16” tubing (figure 2).

Production in the 3/16” tubing and the 1/4” tubing was slightly lower in relation to the 5/16” tubing the second season which is more likely a result of the shorter season.

With more trees per lateral, the results were very different.

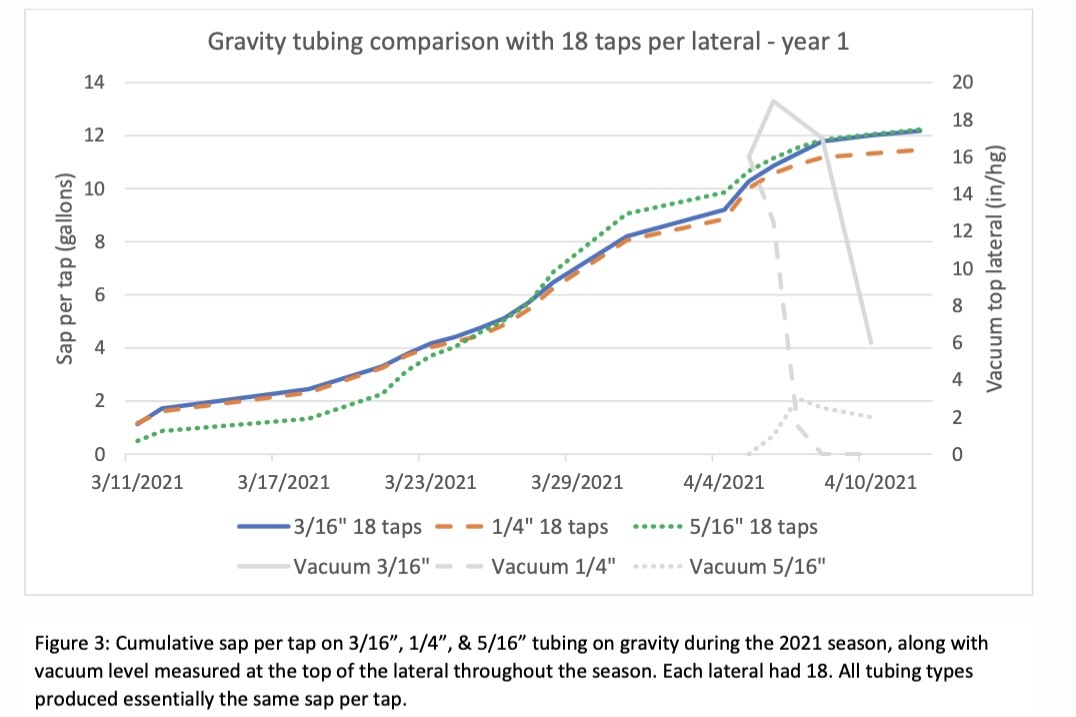

With 18 taps per lateral, all three tubing types produced equal amounts of sap (figure 3).

Vacuum gauges were not added to the 18 tap per lateral and 30 taps per lateral line initially and with the short season in 2021 most of the heavy flows were missed.

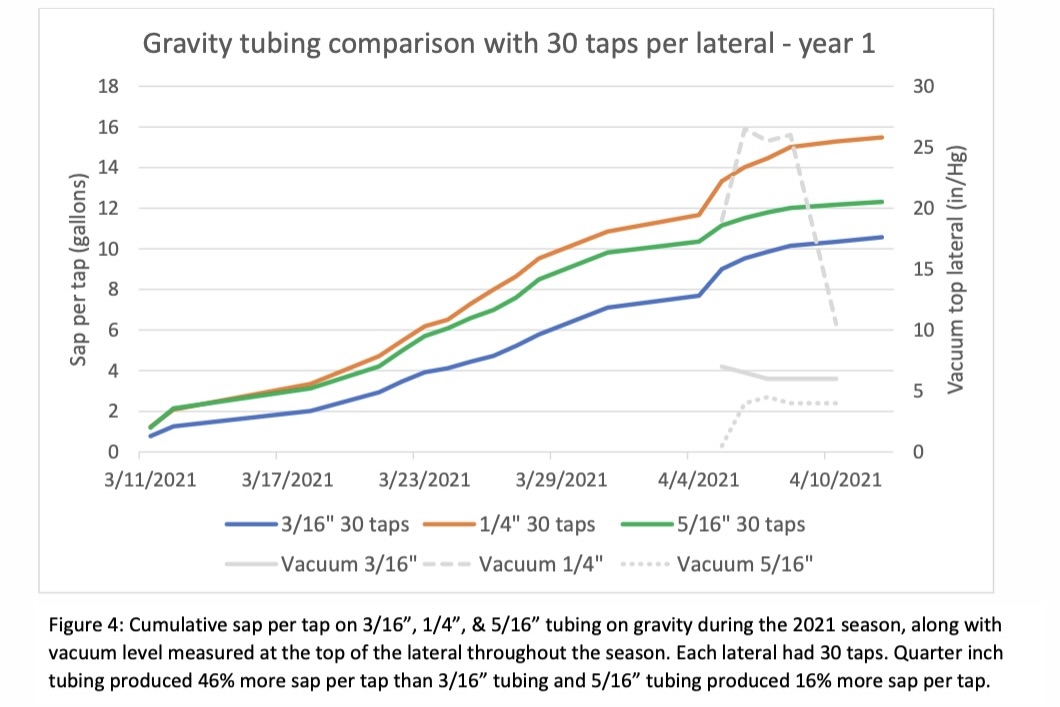

In 30 taps per lateral, 1/4” tubing had the highest production with 46% more sap per tap than 3/16” tubing and 5/16” tubing produced 16% more sap per tap than 3/16% tubing (figure 4).

This confirms previous research that when more trees are added to larger diameter tubing, vacuum can be created (Morrow, 1972).

However, it can be challenging to find this many trees in a lot of applications unless a very large slope is available.

In a small trial of 1/4” tubing on a vacuum system it performed equal to 5/16” in year one and slightly less in year 2 (data not shown).

On a vacuum pump system 5/16” tubing is still probably the ideal tubing while in gravity systems 1/4” tubing has promising potential.

After two years of comparing 3/16” and 1/4” tubing, plugging was not observed in the tubing.

We will be repeating the study during the 2022 sap season for a third year on 8 &10 taps/lateral and the second season on 18 & 30 taps/lateral.

A lot of research is still needed to determine the effectiveness of 1/4” tubing. We don’t want to rush into promoting 1/4” tubing until we are confident plugging will not be an issue.

From our initial study 1/4” tubing is showing promising results. It is anticipated that plugging will not be an issue as it can be with older 3/16” tubing that has not been sanitized.

Over time, 1/4” tubing will more than likely produce higher yields than 3/16” tubing. If so, 1/4” tubing maybe an alternative tubing option for gravity tubing systems.