BACK TO HOME

Cornell Corner

Making bucks from the buddy

Aaron Wightman | January 7, 2021

VAN ETTEN, N.Y.—Does buddy syrup have potential high-value uses?

That is the subject of a new research project at Cornell University, where maple specialists are investigating a wide range of value-added options for this much maligned, late-season flavor.

Maple trees enter a period of dormancy at the end of each growing season.

This is an adaptation that allows trees to survive the cold of winter. An important aspect of that survival strategy is the management of energy reserves in the form of sugars and starches. [ MORE ]

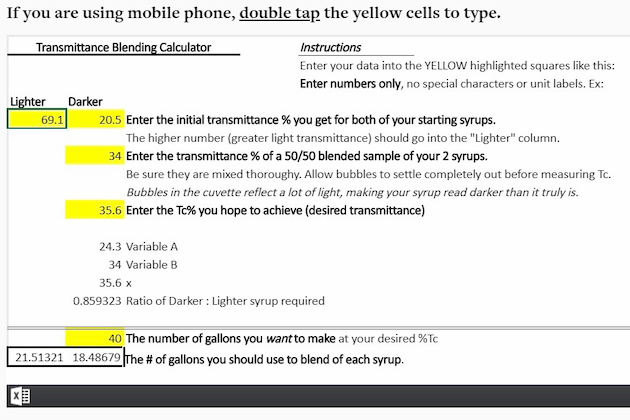

Grade Blending – a new calculator to get your syrup in grade

Ailis Clyne Technician, Cornell Maple Program Cornell University, Department of Natural Resources | October 7, 2020

VAN ETTEN, N.Y.—Have you ever wanted to blend two syrups of different grades to meet your customers’ needs?

The Cornell Maple Program has developed a new user friendly tool to calculate how many gallons of each syrup you would need to blend.

This calculator will only help those of you using digital light meters that give you the percentage of light transmittance (%Tc) through your syrup.

It won’t help if you use a visual kit.

[ MORE ]

Beech syrup can add value to your operation out of pesky trees

Adam Donald Wild | September 14, 2020

LAKE PLACID, N.Y.—Love ‘em don’t hate ‘em.

You know those pesky beech trees growing so thick in your sugarbush it makes it hard to walk through and when you do, they slap you in the face? Well, we are tapping those beech trees for syrup production.

Yes, you read correctly, we are tapping American beech (Fagus grandifolia) trees at Cornell University’s Uihlein Maple Research Forest in Lake Placid, NY. Since the infestation of beech bark disease throughout northern forests beech trees have been rendered to little economical value besides firewood.

By tapping the trees for sap collection, it may be possible to create value from the beech trees in your forest.

[ MORE ]

Get Brewing with Maple Beer

Aaron Wightman, Cornell Maple Program Extension Associate | August 17, 2020

VAN ETTEN, N.Y.—How ‘bout a cold one?

As maple production continues to increase, product diversification becomes an increasingly important strategy for maintaining industry profits.

Craft beers that feature maple syrup as a prominent ingredient represent a large potential market opportunity.

The Cornell Maple Program is working with brewing experts to create guidance for the best use of maple in making high quality beers.

Brewing beer with maple syrup or sap is not a new practice. Many hobbyists and even a few commercial scale breweries have produced beers with a maple component for years.

However, with the continued growth of the craft brewing industry, the beer industry may hold untapped opportunities for sugarmakers.

[ MORE ]

Bleaching and double-tapping part of maple tubing trials on 5/16 lines from Cornell

Steve Childs, New York State Maple Specialist | July 13, 2020

VAN ETTEN, N.Y.—During the 2020 maple season five treatments were tested on 5/16 lines at the Arnot Forest Research Forest.

Each treatment was repeated 4 times in the Arnot Forest sugar bush and each of these replications had four taps on a single lateral line.

The first sap runs were recorded on February 1 and the last reading was recorded on March 30.

The treatment used as a check used old spouts and drops where the drop has been used for 8 years and the spout has been in use for 5 years.

Lines had been vacuumed dry at the end of previous seasons when the taps were pulled but received no other cleaning.

The second check for standard comparison is new drops and spouts while the lateral lines were not replaced.

This year the old system yielded 26.1 gallons of sap per tap while the all new spouts and drop system yielded 40.7 gallons of sap per tap representing an increase of 14.6 more gallons of sap per tap. [ MORE ]

Double-tapping trees might yield results, say Cornell researchers

Kara Lynn Dunn, Northern NY Agricultural Development Program | June 15, 2020

LAKE PLACID, N.Y.—Retapping trees could result in 20 percent more sap.

“Recent projects that looked at the optimum time for tapping maple trees indicated that early tapping to capture early season sap runs and re-tapping later in the season could have potential to increase syrup production yields by at least 20 percent or a $6 per tap profit increase,” said Adam D. Wild, director of Cornell University’s Uihlein Maple Research Center.

This season Wild is conducting trials to test the feasibility of re-tapping maple trees during the sap season. His research is funded by the farmer-driven Northern New York Agricultural Development Program (NNYADP), which is helping regional maple producers evaluate and add opportunities to increase sap and syrup production.

Sugarmakers shouldn’t rush out to re-drill trees just yet. Wild said the feasibility of the method needs more data, which he hopes to collect and publish this spring.

[ MORE ]

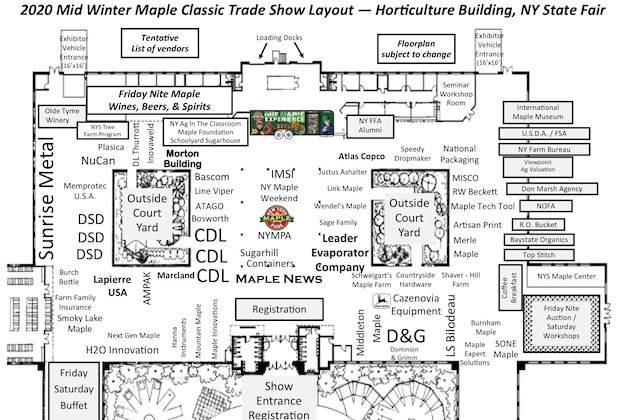

Mid-Winter Classic Maple Show this weekend

Peter Gregg | January 2, 2020

SYRACUSE, N.Y.—This year’s Mid-Winter Maple Classic will take place on tomorrow and Saturday, January 3 and 4 at the New York State Fairgrounds in Syracuse. It's the biggest maple trade show of the year and typically draws more than 1,000 sugarmakers, venders and educators.

This is the second year the conference will be held at this location which offers a large space to fit the entire trade show, and meeting rooms that can accommodate larger audiences.

The day-and-a-half event will be hosted by the New York Maple Producers Association in conjunction with the New York FFA Alumni Association and Cornell Maple Program. The conference will follow a similar format as previous years.

[ MORE ]