Cornell Corner

It could be the T's

Results on 3/16th testing by Cornell researchers find plugged T's might be the cause of second year drop off

By STEPHEN CHILDS, NYS MAPLE SPECIALIST | NOVEMBER 7, 2019

ITHACA, N.Y.—The results of tests conducted in the 2019 sap season at the Cornell Arnot Forest has clarified one important question: Why do we experience yield loss with 3/16th tubing after the first year?

This was the fourth season where experiments were run using 3/16 tubing with true 3/16 fittings and Ts.

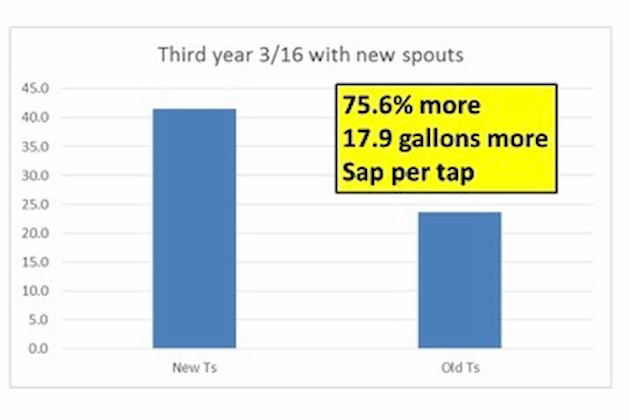

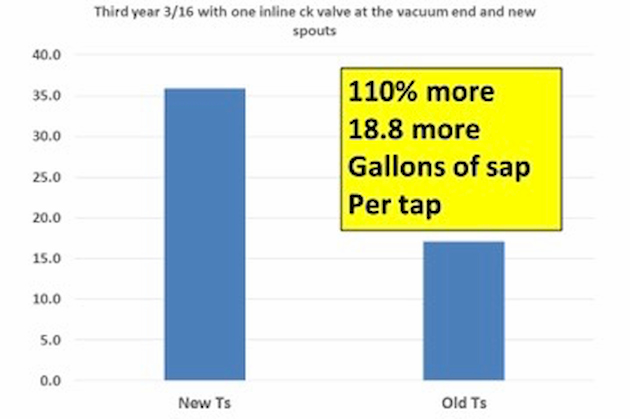

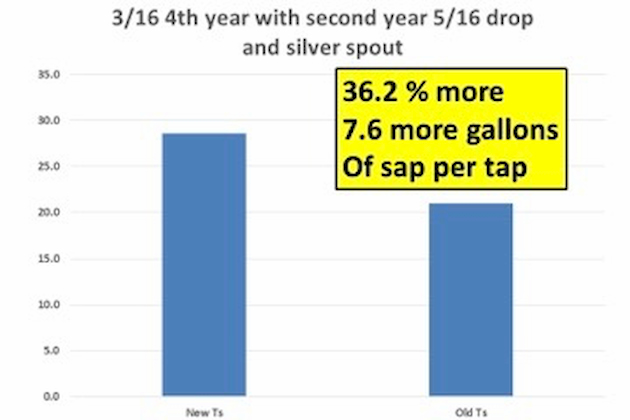

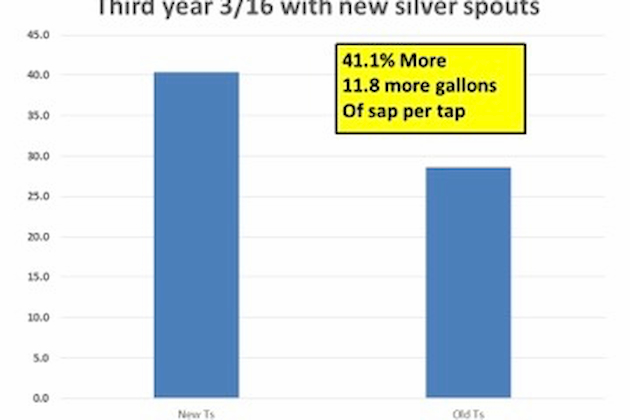

A variety of different combinations of spouts, drops and cleaning methods were tested, but in each case the age of the T was the primary yield controlling factor while the method of tap hole sanitation used in the test was secondary.

For each test, half of the replicates received new Ts for the 2019 season, and half remained two, three or four years in use.

The charts above reflect the dramatic difference between sap yield per tap where the new Ts were installed and where they were not.

In 2018 we tested second year 3/16 tubing with brand new check valve spouts which resulted in poor yield represented by the second bar down in the chart below.

This lead us to believe that the check valves had failed for the first time in all the tests we had conducted on them.

It is now my opinion that it was the T's that were plugging making the check valves appear to be ineffective.

The treatments in 2018 that had been upgraded to a 5/16 drop also received new Ts but other connectors in the system were not changed likely causing the somewhat lower yield than the all-new 3/16 treatment.

In the coming year we will be testing a variety of treatments that will attempt to overcome this T plugging problem.