BACK TO HOME

UVM Proctor Page

Effective marketing strategies for sugarmakers

Zac Smith, UVM Ext. | November 26, 2024

BERLIN, Vt.—Maple producers need a comprehensive marketing approach that blends traditional methods with digital strategies.

This integrated approach enhances brand visibility, engages customers, drives sales, and builds a loyal community.

By focusing on five key areas, maple businesses can create a sustainable brand that resonates with consumers and stands out in the marketplace.

Let’s start with branding. A strong brand identity is the foundation of successful marketing.

For maple producers, this goes beyond creating a logo or website. It's about developing a narrative that captures the essence of your products – their quality, tradition, and sustainability.

This story should be consistently reflected across all platforms and materials, from product packaging and promotional materials to your website and social media profiles. [ MORE ]

Syrup yields not equal across all operation sizes

Mark Isselhardt, University of Vermont Extension Maple Specialist/Maple Program Leader | October 2, 2024

MORRISVILLE, Vt.—The USDA Census of Agriculture was published last winter. Many interesting trends were seen in the data.

Maple production numbers in the 2022 Census tally saw the total number of U.S. taps rise to 17,970,611; a 21% jump from the 2017 Census of 14,864,604.

The largest gains in taps were found in the largest sized operations (>10,000 taps) which saw 2.6 million new taps compared to 2017.

This significant growth was contrasted by little apparent change in the total number of maple operations between 2017-2022.

In 2017 there were a total of 9,462 operations reporting maple production.

This number grew by 104 (1%) over the 2017-2022 timeframe.

The yield of syrup (gallons of syrup/tap) is a metric that producers will use when deciding on whether to make investments in sap collection technology. [ MORE ]

UVM names new director of Proctor Maple Research Center

Peter Gregg | July 17, 2024

UNDERHILL CENTER, Vt.—Dr. Tim Rademacher has been named the new director of University of Vermont’s Proctor Maple Research Center, taking over from longtime director Dr. Timothy Perkins, who retired last year.

Rademacher will assume duties at Proctor this fall, overseeing research projects and managing permanent staffers and student researchers. Proctor is the 300-acre field research station of the Department of Plant Biology at the University of Vermont.

Born in Germany, Rademacher’s did both his undergraduate and doctoral work at Cambridge University in England and post-doctoral work at Harvard University in the university's research forest in Petersham, Massachusetts.

For the last year and half he has been permanent researcher in forest ecophysiology and sustainable development at Centre ACER. He also was an associate professor at the University of Quebec in Outaouais. [ MORE ]

Online syrup orders fail for quality

Peter Gregg | February 14, 2024

MORRISVILLE, Vt.—Onlne maple syrup orders continue to have quality issues, according to Vermont researchers.

“We saw twice as many flavor problems this year,” said UVM Extension maple specialist Mark Cannella, who along with UVM Extension maple specialist Mark Isselhardt, conducted an anonymous survey of online syrup purchases this summer, repeating a study they conducted in 2021.

Not much has changed.

The researches purchased online 91 samples each of Golden and Dark syrups from 30 different producers in nine different states, including Vermont, New York, New Hampshire, Michigan and Connecticut.

Samples were tested for clarity, color, density and flavor.

Three pints of each grade were bought in July and the testing was conducted in early August.

“The dark syrups had a much higher rate of off flavor” Cannella said, during a presentation sponsored by the Vermont Maple Sugar Makers Association on Dec. 6. [ MORE ]

Quick tips to achieve higher sap yield

Dr. Timothy Perkins, Director, UVM Proctor Maple Research Center | January 22, 2024

UNDERHILL Ctr., Vt.—Increasing the yield of sap from maple trees is the goal of most maple producers.

While getting there isn’t a matter of one simple thing, by following best management practices and paying attention to detail it is possible to increase sap yields, often quite dramatically.

Tubing System Design and Installation – To achieve good vacuum and sap transfer in tubing systems, producers should design and size their systems for peak flows.

Undersized mainline or systems installed without adequate slope or with sags will not perform well.

Optimal mainline installations have 2-4% slopes with lateral lines running uphill from mainline. Even small sags will impact air and gas flow negatively.

Lateral lines should follow the “strive for 5, no more than 10” taps per 5/16” lateral line recommendation. [ MORE ]

Spout deployment: Late fall, early winter, late winter?

By TIMOTHY D. PERKINS and WADE T. BOSLEY | December 20, 2023

UNDERHILL CENTER, Vt.—The influence of spout and dropline sanitation practices on sap yield has been widely studied over the past 15 yrs.

There are a wide variety of methods to achieving good sanitation in tubing systems.

The choice of which approach to utilize largely comes down to producer goals, economics, and personal choice.

In the United States, sanitation is largely achieved through the annual replacement of spouts (with regular or check- valve spouts).

This replacement approach is also employed by some producers in Canada, but is less common due to the wide- spread use of isopropyl alcohol, which is not permitted as a sanitizing agent in maple tubing systems in the U.S.

What is less well understood is the effect that other associated practices sometimes employed in the replacement strategy has on sap yield.

At the Proctor Center, Perkins, van den Berg and Bosley demonstrated that sap production is not significantly different when new spouts are deployed in the field in the late-fall preceding sugaring season, in January before the season, or during tapping time. [ MORE ]

Whatever happened to the 'sap cap' experiment?

Peter Gregg | December 5, 2023

UNDERHILL CTR., Vt.—Whatever happened to the sap cap experiment?

That is a common question asked about the program at the UVM Proctor Maple Research Center which studied the feasibility of collecting sap from saplings.

UVM researchers found that either a plantation of saplings or groups of young trees in a sugarbush needing to be thinned were appropriate to collect sap with this approach.

The problem? The method didn't catch on with equipment manufacturers. [ MORE ]

Sugarmakers are urged to focus on quality, especially for fair contests

Peter Gregg | July 11, 2023

BUCKLAND, Mass.—Sugarmakers are urged to focus on quality, and double check your syrup for fair contest entries.

“Quality sometimes takes a backseat to overall production,” said Mark Isselhardt, UVM Extension Maple Specialist and the guest speaker at the Massachusetts Maple Producers Association annual meeting.

Isselhardt, who is a frequent syrup tasting judge at various contests, made a point about the disqualification rates for entries.

He said at some recent judging contests there was a 62 percent rejection rate.

At the Chittenden County Fair in Vermont, 15 entries were rejected out of 24.

At the Vermont Maple Festival in St. Albans last year, Vt. 45 entries were rejected out of 91. [ MORE ]

Ewwww. Bent syrup

Peter Gregg | January 25, 2023

MORRISVILLE, Vt.—Ewww, bent syrup.

Producers are being advised to keep an eye on quality as a new maple season gets underway.

One of the things to watch out for are changes in the sap at the end of the season, or whenever warm temperatures strikes, which can cause nasty effects.

UVM Extension Maple Specialist Mark Isselhardt says the ropey syrup phenomena, sometimes so thick that you can bend it with your finger, is caused by a bacteria that produce exopolysaccharides (EPS). [ MORE ]

UVM offers a new contract template for sap sellers

Mark Cannella, University of Vermont Extension | October 5, 2022

MORRISVILLE, Vt.—What could be worse than a ten-page legal contract?

Perhaps an eighteen-page legal agreement is a “non-starter” and you would rather bear the risk if something goes wrong.

Educators at UVM were hesitant to publish a long version for the new Sap Non-Exclusive Supply Agreement knowing that the common practice is a handshake agreement.

The challenge we faced from legal professionals and maple producers we consulted with was that there so many different considerations that could not be ignored.

The result is a robust and inclusive educational document/legal agreement template that enables a sap supplier and sap buyer to negotiate and agree to important terms guiding the arrangement.

The Maple Sap Non Exclusive Supply Agreement and an Additional Clauses Supplement factsheet are available online in the Resource Library at www.maplemanager.org [ MORE ]

Syrup tasters sought for UVM experiment

Peter Gregg | July 6, 2022

UNDERHILL CENTER, Vt.—The UVM Proctor Maple Research Center is seeking participants July 19-20 for a maple syrup flavor experiment.

The experiment will involve tasting several samples of pure maple syrup and assessing their flavor.

To participate as a panelist, you must:

— Have experience tasting and evaluating the flavor of maple syrup (or have completed the IMSI Grading School or other syrup flavor training)

— Be at least 18 years old

— Be a healthy, nonsmoker [ MORE ]

Got jumping worms?

Peter Gregg | December 8, 2021

MONTPELIER, Vt.—Got jumping worms?

Vermont sugarmakers are being asked to participate in a survey to find out if jumping worms have been found in the sugarbush.

This short survey will determine how widely distributed the jumping worms are in Vermont.

https://forms.office.com/Pages/ResponsePage.aspx?id=O5O0IK26PEOcAnDtzHVZxsFmcMWPh6dMjZ68WQU-7N5UNjhXM09MR1RKVFVOSkQ0UDlIWlhTVjQ1TC4u

The Vermont Agency of Agriculture, Food and Markets and the VT Urban and Community Forestry program are interested in finding out more about the distribution of jumping worms, Amynthas sp., in Vermont.

[ MORE ]

Maple University! Vermont maple school online this week

Peter Gregg | December 7, 2021

RANDOLPH, Vt.—Call it Maple University.

Sugarmakers everywhere are invited to Vermont’s three-day maple school this week, starting Wednesday.

“We'll be offering three days of engaging sessions,” organizers said.

Registration is free. Click on: https://www.eventbrite.com/e/2021-vermont-maple-conference-week-tickets-221510141797

Sugarmakers in need of assistance with registering online call Cory (802-786-9437) or Allison (802-777-2667).

All conference sessions qualify for Continuing Forestry Education credits.

[ MORE ]

Sap flow, wounding and compartmentalization in maple

Timothy D. Perkins, Abby K. van den Berg, and Mark L. Isselhardt | June 23, 2021

Why the sap may not always flow well in the early season

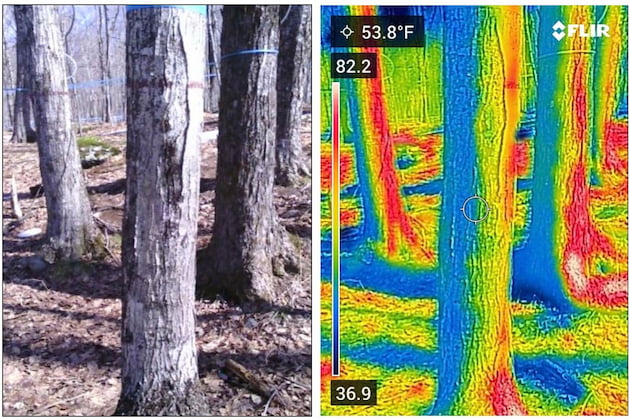

Timothy D. Perkins, Abby van den Berg, Brendan Haynes | May 7, 2021

UNDERHILL CTR., Vt.—Maple producers know that when the temperature starts to rise in the spring, sap flows can’t be far behind.

But when the weather starts to warm early in the spring and temperatures seem favorable for good sap flows, they are sometimes left wondering why the sap hasn’t started to run.

There are several explanations for the disconnect between warm air temperature and a lack of flow during the early season.

First, trees are big and can have a large amount of thermal inertia (resistance to change).

By that we mean that tree temperature is buffered and will not always respond quickly to changes in air temperature.

Whereas air temperature can rise quickly during the day, it takes a while for the large mass of wood to warm up, particularly if it has been very cold prior to a warm period. [ MORE ]

Getting it right. Tapping tips for higher sap yield

Dr. Tim Perkins & Dr. Abby van den Berg | January 21, 2021

UNDERHILL CENTER, Vt.—Tapping. It isn’t as easy as simply drilling a hole in a tree.

Getting a good taphole in a good location is critical to achieve high yields.

Start with a sharp bit designed specifically for maple tapping, and sharpen or replace it after drilling about 2,500 holes.

[ MORE ]

Vermont researchers downplay fall tapping

Peter Gregg | November 10, 2020

UNDERHILL CTR., Vt.—Thinking about tapping this fall? Don’t bother.

That’s the message from Abby van den Berg, a research scientist at the Proctor Maple Research Center in Underhill Center, Vt. who hosted a compelling webinar on the topic last month.

“Generally speaking from a yield perspective, the data suggests fall tapping is not the best idea, especially factoring in all the extra things involved,” she said.

Dealing with extensive freeze and thaw cycles, tapping five feet in the air to account for winter snows in northern regions were just two of the big hassles that come with tapping extra early.

[ MORE ]

Stay away from the dead wood when tapping say Vermont researchers

Paul Post | October 20, 2020

UNDERHILL CTR., Vt.—Stay away from the dead wood.

Sugarmakers should maintain a large amount of clean, conductive wood in their trees, which will make sure the tree has a functional water transport system and is at relatively low risk of disease and decay.

That was the message from industry expert Abby van den Berg, University of Vermont research associate professor and assistant director of the Proctor Maple Research Center.

She was the host “Tapping Practices to Optimize Sustainability and Yields,” a webinar hosted by the Virginia Tree Syrup Program last month.

“But it also means we have a high probability of hitting clean, conductive wood when we tap,” van den Berg said. “That means we’re going to maintain sustainability of yields as well.”

Promoting healthy, radiant growth of trees is the underlying basis for ensuring maple production’s long-term success and profitability. [ MORE ]

Zoom maple! UVM offering fall series of maple education seminars online

Peter Gregg | September 16, 2020

MORRISVILLE, Vt.—Time for virtual maple.

This fall University of Vermont maple specialists will will continue their series of online webinars focused on business decision-making and forestry practices.

Sugarmakers across the U.S. are invited to learn about the best ways to integrate business management and sugarbush management for a thriving maple enterprise that targets profits and forest health.

Topics will include sap yields, sugarbush forestry, tubing systems, sap-only enterprises, sugarbush appraisal and more.

[ MORE ]

Tapholes – Straight or Slanted? The sap doesn't care

T.D. Perkins and W.T. Bosley, University of Vermont Proctor Maple Research Center | June 10, 2020

UNDERHILL CTR., Vt.—Straight or slanted? The sap doesn’t care the angle of your spout.

Historically it was recommended that tapholes be drilled at a slight angle to allow sap to run out to reduce freeze heaving of spouts and to reduce sap souring in the taphole.

Starting shortly after the introduction of the “small” spout (19/64”, 5/16”), maple equipment manufacturers started to recommend that tapholes be drilled straight in.

The most common reason for this was stated that it avoided the creation of oval tapholes. [ MORE ]

Rental rates and leases to right size your business

Mark Cannella, UVM Extension | April 14, 2020

MORRISVILLE, Vt.—Getting to at least 5,000 taps and utilizing rented trees may be the key to economic viability, according to new research from University of Vermont Extension.

Getting a maple business to a profitable scale is a primary goal for commercially-minded producers seeking meaningful income from their business.

A large equipment investment is needed to run a modern and efficient maple enterprise.

The prospect of purchasing more forestland may not be financially feasible for everyone that seeks to expand their enterprise.

Renting taps from other landowners can be a good approach to access more woods when a land purchase is not immediately possible. [ MORE ]

Addison County (Vermont) Maple Seminar has big class schedule this Saturday

Peter Gregg | January 9, 2020

MIDDELBURY, Vt.—The maple school season in Vermont kicks off this weekend, with a big show in Middlebury this Saturday, Jan. 11.

The 2020 Addison County Maple Seminar will be held at the Middlebury Union High School and will feature a day-long slate of classes and demonstrations for the small and big producer alike.

Walk-in registrations are welcome and the fee will be $35 for the day, including lunch (or only $20 without the lunch).

The high school is located on 73 Charles Ave. in Middlebury. The show begins at 8:00 a.m. and runs to 3:45.

The program is run by the Addison County Maple Sugar Makers Association in conjunction with the UVM Proctor Maple Research Center and UVM Extension.

Sponsors of the show include CDL USA, Co-operative Insurance Companies, F.W. Webb Company, National Bank of Middlebury, Vermont Economic Development Authority (VEDA). [ MORE ]

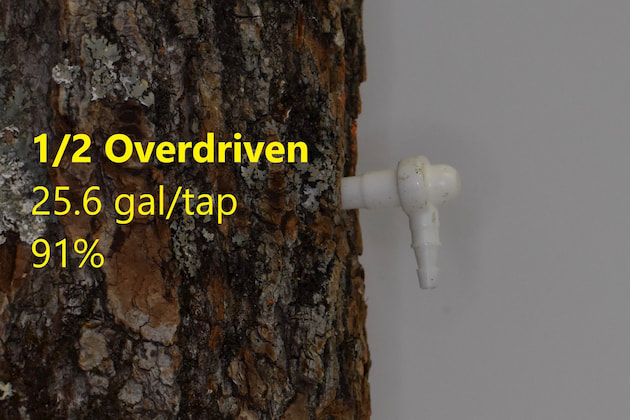

The Goldilocks Touch

T.D. Perkins, W. T. Bosley and A.K. van den Berg | November 6, 2019

UNDERHILL CENTER, Vt.—One of the more common questions producers have when about tapping maple trees is “how deep should spouts be driven in to the taphole?”

Unfortunately, there is not a simple answer, since different spouts have different dimensions, variable degrees of taper and steps and are made of different materials with dissimilar degrees of “stickiness.”

Regardless, the importance of driving spouts in to the proper depth is readily apparent: if spouts are driven too shallow there is a risk that spouts can leak vacuum or heave easily during freezes, but if driven too deeply, small cracks may form which cause liquid and vacuum leaks or alternatively, the reduced amount of exposed wood surface area inside the taphole caused by driving spouts in too deeply may reduce sap collection.

Most frequently, producers drive in spouts by sound – a change to a “deader” sound indicating proper depth. However some producers feel that seating spouts more deeply than this lowers the chance that spouts will heave and cause leaks and a loss of vacuum, therefore reasoning that deeper spout seating reduces maintenance during the season. [ MORE ]

Price-Setting for maple sales

Mark Cannella | October 16, 2019

MORRISVILLE, Vt.—Prime-time maple retail season is picking up! It is time to welcome leaf peepers into our glorious northern woodlands, gear up for holiday sales and revisit price points for local demand.

I have worked with dozens of maple producers and retailers in recent years. Everyone wants to make more money and smart price-setting strategies are the key to meeting financial objectives.

It is common for people to scoff at a neighbor who apparently prices dooryard maple gallons too low. Who is selling syrup for $35 per gallon?

It is increasingly common for people to scoff at that new business selling pints online for $22+ in fancy glass bottles (aka expensive glass!). Whatever! Stop judging others and double-down on your own pricing strategy. [ MORE ]

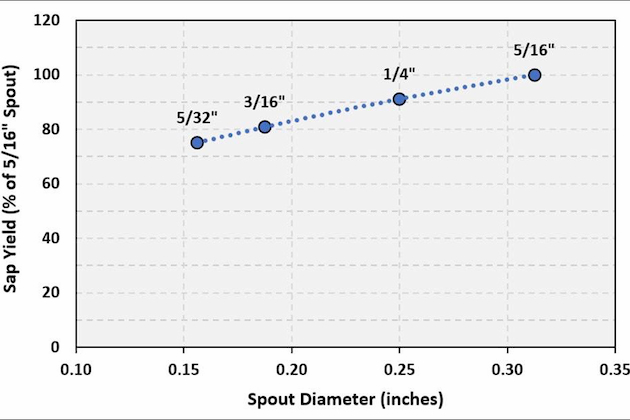

UVM Proctor Center examines effect of spout diameter on sap yield

T.D. Perkins & A.K. van den Berg UVM Proctor Maple Research Center | August 29, 2019

UNDERHILL CENTER, Vt.—In order to determine the optimal approach to sap collection in their operation, maple producers need to be informed about how the choices they make will affect sap yield.

One of the decisions they face is what spout size (diameter) to use.

Average sap yields from tapholes of different diameters as a percentage of yields from 5/16”-diameter (control) tapholes. [ MORE ]

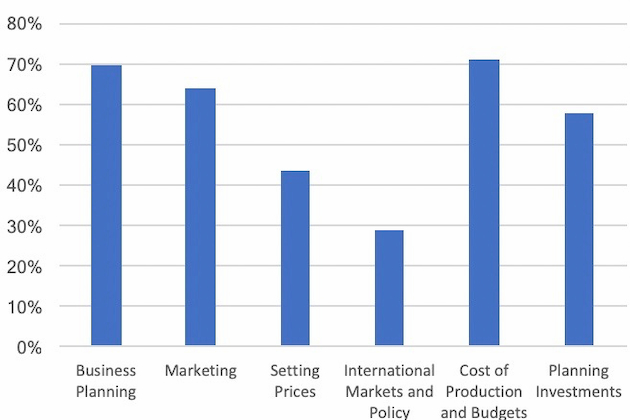

Maple producers doing more business planning

Mark Cannella, University of Vermont Extension | June 5, 2019

MORRISVILLE, Vt.—Maple operators are talking more and more about business each year.

The number of participants at business workshops has doubled or tripled at most winter maple conferences between 2014 and 2019.

A combination of public comments at these sessions and private discussions has revealed many reasons why maple operators are paying more attention to business planning.

Three major themes stand out from my interactions with producers and sellers: finances, marketing and collaboration.

Finances and profitability goals are top of mind.

New and expanding enterprises remain optimistic and opportunistic. Investment continues and the large expense forces owners to maintain cash flow and strive for a long-term return.

A recent lag in bulk prices is forcing many managers to reassess their cost of production and adapt to sub $2.30 per pound bulk markets.

Strong marketing plans strengthen the business. Sellers at all levels are feeling competition and working hard to distinguish their quality, products and brands.

Bulk producers are seeking premiums for certified organic syrup. [ MORE ]

Proctor Center continues with innovations

Jeff Wakefield | September 10, 2018

UNDERHILL CTR., Vt.—Like most sugarmakers, Brian Stowe was used to working without a break from the start of the maple sugaring season in early spring to its bitter end in mid- to late April.

“If you had dental or medical issues, taxes, anything – all that had to be done before or after; during the season, you’re committed, 24/7,” says Stowe, sugarhouse operations manager at the University of Vermont’s Proctor Maple Research Center.

But after 28 sugaring seasons at the Proctor, Stowe encountered something new this year: weekends off.

Stowe owed his newfound down time to a combination of state-of-the-art new and cleverly re-purposed old technology at the Proctor sugarhouse, a model facility for the maple industry. If the innovations catch on as past improvements have, the Proctor’s innovations could make sugar-making a vastly more humane, and profitable, enterprise in the future.

What first greets a visitor to the sugarhouse, a peaked two-story structure tucked in a grove of maples down the road from the Proctor’s main research facility in Underhill, is a sea of steel barrels just inside the door that contain the operation’s output for the year: 3,000 gallons of maple syrup, a record crop.

But it isn’t the quantity of maple syrup that made 2018 such a banner year, says Tim Perkins, a research professor in UVM’s Plant Biology Department who is the Proctor’s director. It was the greatly reduced time it took to produce it – an improvement that was responsible for Stowe’s more forgiving schedule.

“In the past we made about 20 gallons of syrup for every hour of sugarhouse time,” Perkins says. “This year we produced 42 gallons of syrup for every hour,” a 110 percent improvement.

[ MORE ]

Understanding the relationship between tree size and yield

Timothy Perkins, Mark Isselhardt, Abby van den Berg | UVM Proctor Maple Research Center and UVM Maple Extension, University of Vermont Underhill Ctr., Vermont | Feb. 5, 2018

There are several important factors that affect the yield of sap from trees during the production season.

These generally fall into four categories: tree characteristics, tapping, vacuum, and spout/tubing sanitation.

On tubing, it is sometimes difficult to observe the impacts each of these has on sap yield, by doing controlled research studies it is possible to discern the relationships among certain characteristics and practices.

In fact, some of the common sayings in the maple industry such as “strive for five, no more than ten” and “5% more sap for each 1” Hg vacuum” come directly from such research.

One relationship that is sometimes overlooked is the one between tree size and yield. [ MORE ]

A snapshot of sugarbush lease rates in Vermont

Mark L. Isselhardt, Maple Specialist | Oct. 6, 2017

Many sugar makers in Vermont own the land on which their trees grow. The land may have been passed down through several generations of family ownership or recently purchased on the open market. Sometimes however, producers will pay landowners for the right to tap trees. Whatever the reason, sugar makers and landowners who decide to enter into an agreement, at a minimum, they must agree on a price and terms before tapping can begin. This is just the beginning however as both landowner and producer need to consider several things before an agreement can be reached. Determining length of lease, minimum tree diameter to be tapped, when payment is made as well as determining what restrictions related other activities (thinning, retubing, road maintenance, etc.) needs to be done before an agreement can be finalized. These and other details should be carefully considered and written into a signed lease agreement. This article will focus on just one part of establishing a lease agreement; a snapshot of the current $/tap for lease agreements statewide. [ MORE ]

Are you watching your profits evaporate?

Mark Cannella | May 2017

Maple sugaring in 2015 was not as profitable as 2014. The record crop in 2016 was able to stabilize overall financial performance but on a pound for pound basis the 2016 profit margins were still down as market prices slipped. [ MORE ]

Off-flavor syrup reference available

Mark L. Isselhardt, Maple Specialist University of Vermont Extension Proctor Maple Research Center | February 2017

A new product to help producers identify off-flavors in maple syrup is available for the 2017 production season.

The product, officially known as the Off-flavor syrup reference set, was developed by the University of Vermont Extension Maple Program. The kits are intended for anyone who works with pure maple syrup, especially those who are responsible for grading pure syrup and are using flavor terminology common to U.S. producers. [ MORE ]

Long-term average a better predictor of air temperature

Tim Perkins, University of Vermont Proctor Maple Research Center | Jan. 2017

Whether it is choosing when to tap, or anticipating when the sap will run (or stop), maple production is intimately tied to the daily change in weather. Producers keep a close eye on their trees, and often an even closer eye on the weather forecast.

Although the weather prediction can provide some level of information about the possibility of impending sap runs, it can sometimes lead to a bit of angst if the forecasted weather appears that it will be too cold or too warm for good flows. [ MORE ]

Devastating caterpillar

By Mark Isselhardt, UVM Extension, Maple Specialist | September 2016

An infestation of forest tent caterpillar or FTC (Malacosoma disstria) has developed in several parts of Vermont this summer. This early-season defoliator is a native insect and has the potential to defoliate large areas of hardwood forest. Sugar maple is one of the caterpillars preferred host trees. [ MORE ]

Some confusion over IPA usage

Various Contributors | March 2016

Increased attention to spout and tubing sanitization has led to rising sap yields for maple producers. Cleaning and replacement (use of new spouts, use of Check-valve spouts or adapters, or replacing spouts and droplines) strategies have different effects on sap yields, and each carry their own costs in terms of supplies and labor to implement the various approaches, and thus each has a different net profit. [ MORE ]

Recent trends in the maple industry III - changes in sap yield

Timothy D. Perkins, M.L. Isselhardt and A.K. van den Berg |

This series of articles has described the changes in the U.S. maple industry over the past 15-20 years. We have witnessed an era of tremendous growth in production, much of it coming about due to the addition of taps. Utilizing the data collected by the U.S.D.A. National Agricultural Statistics Service, it is easy to see that one of the more striking changes though has been the increases in the quantity of sap per tap (sap yield) that producers are now able to collect. [ MORE ]

Recent trends in the maple industry II: U.S. expansion

Timothy D. Perkins, M.L. Isselhardt and A.K. van den Berg |

This second series installment focuses on expansion in the maple industry over the past ten years. We will primarily rely upon the 2012 U.S.D.A. Census of Agriculture (COA) as a basis for our information. In addition, although growth is evident in many maple-producing areas, we will focus primarily on the six top producing states, NH, PA, OH, ME, NY and VT, as these account for over 85% of the syrup made in the U.S.

[ MORE ]

What's trending

By Timothy D. Perkins, M.L. Isselhardt and A.K. van den Berg |

This second series installment focuses on expansion in the maple industry over the past ten years. We will primarily rely upon the 2012 U.S.D.A. Census of Agriculture (COA) as a basis for our information. In addition, although growth is evident in many maple-producing areas, we will focus primarily on the six top producing states, NH, PA, OH, ME, NY and VT, as these account for over 85% of the syrup made in the U.S.

[ MORE ]

Tech helped boost yields in last decades

By Timothy D. Perkins, M.L. Isselhardt and A.K. van den Berg |

Pure maple syrup is a uniquely North American food product that is marketed worldwide. The last few decades have witnessed tremendous changes in the maple syrup industry in the U.S. and Canada. Production of syrup and marketing of syrup have risen dramatically, especially over the past decade. [ MORE ]

Maple water: A first look

By Timothy Perkins, Abby van den Berg and Mark Isselhardt |

Drinking tree sap is common in several areas of the world, but is far less practiced in North America. Several new maple-sap derived beverages have been introduced into the consumer market and prominently featured in news articles over the past year.

[ MORE ]

Birch can help increase your maple operation profits

By Abby van den Berg, Timothy Perkins and Mark Isselhardt |

Birch syrup production is similar to maple syrup production – it uses mostly maple equipment (spouts, buckets or tubing, evaporators, etc.), and the spring sapflow season begins just as the maple season is ending. [ MORE ]

Aesthetics of sap collecting

Tim Wilmot, UVM Extension |

Each year many new people try their hand at sugaring, and discover how satisfying it is to share syrup made with their own hard work. Most sugarmakers take great pride not only in their syrup, but in the entire process of maple production. Remember that whether you produce 2 gallons or 2000, you represent the maple industry to the public. You are making a specialty food product that is pure and natural, and your maple operation should reflect this fact. It is important to set a standard that gives the public confidence in your operation, even if it is very small.

[ MORE ]

Measuring sap flow

By Mark Isselhardt and Tim Perkins |

Over the past several decades we have used several different methods to measure sap volume. With a bucket it is fairly simple….when the system is under vacuum it becomes more challenging. At the University of Vermont Proctor Maple Research Center, we employ a combination of simple recording counters mounted on mechanical vacuum releasers to measure sap production. We are frequently asked by maple producers for details on how we accomplish this and how they might set up something similar in their operations. [ MORE ]

The 3/16 phenomenon

Tim Wilmot |

Gravity tubing systems typically do not perform well compared to systems connected to modern vacuum pumps; however, there are new options today for creating high vacuum in gravity tubing. As many people know, a system using tubing with an interior diameter of 3/16” has been developed in recent years at the University of Vermont Proctor Maple Research Center and has shown considerable success in a variety of locations. [ MORE ]

Testing tapping depth vs. sap yield

Tim Wilmot |

Although it is one of the more significant factors controlling the amount of sap we collect, there is little current published information that examines the relationship between taphole depth and sap yield under vacuum conditions. [ MORE ]

Cloudiness’ affect on refractometer measurements

Mark Isselhardt and Timothy Perkins |

Accurately measuring density is critical to the production of pure maple syrup. Historically, sugarmakers have relied on thermometers and or hydrometers to determine when syrup has reached the desired density. These instruments remain valuable tools today. Refractometers are another tool that can be used to make precise density measurements. [ MORE ]

Using Smartrek vacuum monitoring system

By Timothy D. Perkins and Mark L. Isselhardt |

Four main factors influence sap yields from maple trees. First there is the tree resource itself. Secondly, weather conditions suitable for stimulating sap flow (freeze-thaw events) must occur to start the process. Thirdly, excellent spout and tubing sanitation practices. Finally, higher vacuum levels. [ MORE ]

Should droplines be replaced when using check valve adapters or spouts?

Timothy D. Perkins |

The Leader Check Valve Adapter (CVA) and Leader Clear Check Valve Spout (CVS) are designed to reduce the amount of sap backflow (sap movement back towards the taphole during pump shutdown, leaks, or releaser dumps). [ MORE ]

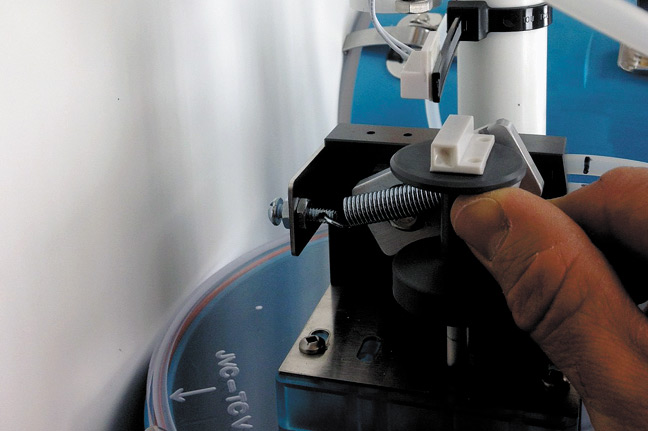

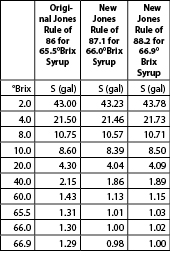

The ‘Jones Rule of 86’ revisited

Timothy Perkins and Mark Isselhardt |

The Jones “Rule of 86” was devised in 1946 by C.H. Jones, a scientist and educator at the University of Vermont.

Originally it was incorporated into a poem that taught several best management practices in a humorous way (see “The maple rule of eighty-six”, reprinted on pages 18-19 of the December 1967 edition of the “National Maple Digest” and pages 129-132 of Maple Sugarin’ in Vermont, by Betty Ann Lockard 2008). [ MORE ]

Proctor comes out with long awaited new tapping guidelines

By Abby van den Berg, Timothy Perkins, Timothy Wilmot, and Mark Isselhardt |

Each year, tapping for sap collection permanently removes a small portion of wood where the spout is inserted. The tree’s response to the wound also results in a column of wood extending above and below the taphole that remains permanently nonfunctional for water transport and future sap collection. Sap collection also removes a portion of the tree’s carbohydrate (sugar) reserves, which are important for supporting the tree’s growth and health. [ MORE ]

Gravity Tubing Experiments — April 2013

Tim Wilmot |

Year 4 of gravity tubing experiments in Underhill, Vermont. This line of 3/16 tubing has 37 taps. [ MORE ]

Exciting new spout research at Proctor continues this season

Timothy Perkins |

Researchers at the UVM Proctor Maple Research Center are working on a prototype spout and stubby combination designed to separate the sap from the gases released by the tree in order to maintain a high level of vacuum at the taphole. [ MORE ]

3 years of research looks at gravity tubing

Tim Wilmot, University of Vermont |

Many maple producers consider gravity tubing, or tubing without the use of a pump, to be a poor substitute for a modern system with a pump, extractor, and the latest tubing arrangement. [ MORE ]

Grant awarded to examine tapping practices

Paul Post |

To Tim Perkins, maple tapping is kind of like taking out a loan.

You can opt for high yield now on smaller trees and wind up paying high “interest rates” or adopt more sustainable practices with a tree’s long-term health in mind that will keep it productive and profitable for decades to come. [ MORE ]

#58, Top Performer

Doug Whynott |

Emerson College professor Douglass Whynott has been working on a book about the maple industry for two years. He has traveled extensively throughout the maple belt collecting stories. This is an excerpt. His book was published by DeCapa Press in 2014. [ MORE ]

Isselhardt appointed as maple specialist

Timothy D. Perkins |

Mark Isselhardt appointed to position of University of Vermont (UVM) Extension Maple Specialist.

Mark will be based at the UVM Proctor Maple Research Center in Underhill Center, where he has been employed for the past 12 years, first as a maple research technician and for the last three as a research specialist. [ MORE ]