Tapping & Tubing

UVM compares 3/16” and 5/16” tubing sanitation

Effectiveness of 3/16ths sanitation methods studied

By T.D. PERKINS AND A.K. VAN DEN BERG, UNIVERSITY OF VERMONT PROCTOR MAPLE RESEARCH CENTER | JANUARY 3, 2020

UNDERHILL, Vt.—It is well recognized that microbial contamination of tubing systems can result in a substantial loss in sap yield if untreated.

Over a decade of research and maple industry experience has produced a range of possible strategies to address sanitation-related issues in 5/16” tubing systems (Perkins et. al. 2019).

Although rapidly adopted by many maple producers, due to the relatively short time period in which it has been in widespread use, there is far less understanding of sanitation in 3/16” tubing systems (Wilmot 2018).

To address this knowledge deficit, we conducted a multi-year study at the UVM Proctor Maple Research Center to examine sanitation-related losses in 3/16” tubing systems to determine which approach(es) might best mitigate sap losses due to sanitation.

In 2015 we set up 12 plots in Underhill, Vermont: half of these had 3/16” tubing and half had 5/16” tubing (both lateral and droplines).

Plots averaged 90.8 taps (range 71-112) and averaged 3 taps per lateral line.

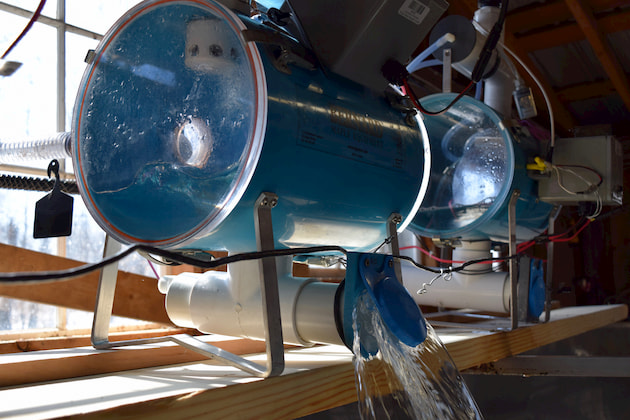

Lateral lines of each plot were connected to individual ¾” mainlines leading to custom mini-releasers equipped with counters (Figure 1).

Each time the releaser would dump sap, the counter was incremented. Releasers were calibrated for the amount of sap dumped each time, thus total sap quantity per tap in each plot could be calculated.

Releasers were connected to a Busch pump operating at 25” Hg vacuum.

Since the lateral lines were installed on slopes, the 3/16” lines should have theoretically added 2-3” Hg of natural vacuum to those lines, producing 10-15% more sap on average.

During the sap flow seasons of 2015, 2016, and 2017, new spouts (S) were installed in all plots each year as controls, since this is the minimum sanitation treatment/practice recommended.

Spouts in all plots were 5/16” with a taphole depth of 2” each year. Spouts were pulled under vacuum at the end of each season (dry-cleaned) and plugged before other treatments were applied.

In 2018, two plots of each treatment line size (3/16” or 5/16”) were equipped with either new standard spouts (S), new Leader check-valve (CV) spouts (C), or new drops (including tees) with CV spouts (D).

In 2019, two of each line size had new spouts (S) installed, had new drops (including tees) with new standard spouts (D), or had lines cleaned with a bleach solution and new spouts installed (B).

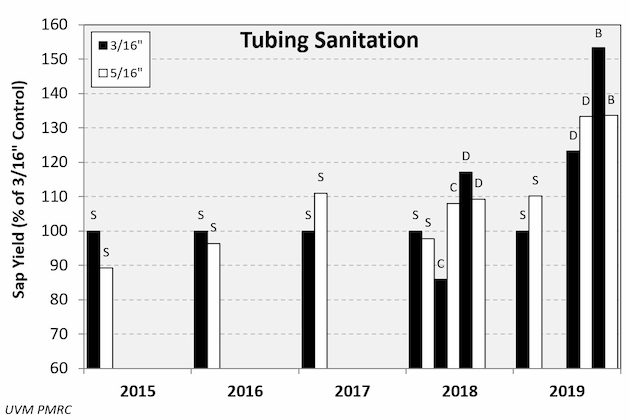

Total sap yields per tap for each plot each year were used to calculate the average sap yield per tap for each sanitation and line size (3/16” and 5/16”) treatment each year and expressed as a percentage of the 3/16” line treatment for that year.

Therefore the 3/16” control treatment is 100% each year, and a corresponding value for other treatments that year above that indicates an improvement due to that treatment, while a reduction from 100% indicates a loss in sap yield.

Results:

In 2015 (first season after installation), as expected due to the additional natural vacuum, 3/16” tubing out-performed 5/16” tubing by 12% (Figure 2).

However, in 2016 3/16” systems produced only 3.8% more sap compared to the 5/16” systems, and by the 2017 season, 3/16” systems produced nearly 10% LESS sap than the 5/16” systems.

This trend occurred despite the fact that new spouts (S) were being used in all the systems each season. This led us to speculate that the 3/16” tubing systems were more susceptible to sanitation-related issues than the 5/16” systems, or that there was something else going on that we did not understand.

In 2018, the 3/16” and 5/16” systems with only new spouts (S) performed roughly the same in terms of sap yield. Adding checkvalve spouts (C) performed as expected in the 5/16” tubing systems in that sap yield rebounded (10.4%).

In the 3/16” systems however, the average yield from check-valve spout lines decreased by over 14%. Similarly, new drops with checkvalve spouts (D) were effective in the 5/16” systems (11.7%), and even more so in the 3/16” systems (17.2%).

The difference in yield between new drops on 3/16” and 5/16” systems was not completely restored however, as the yield increase between the two tubing diameters, rather than being between 10-15% as predicted and observed in the first year of the study, was only 7%.

Due to the lack of observed restoration of sap yield with check-valve spouts, and the incomplete restoration of sap yield with new drops, we concluded that 3/16” tubing systems were clearly being impacted by some factor other than the relatively straight-forward sanitation issues we observe in 5/16” systems, and that the most likely explanation was plugging of fittings (tees and connectors) in 3/16” systems.

We were unable to find clear widespread evidence of plugging however, despite considerable effort spent searching after the 2017 and 2018 seasons.

If plugging was the explanation, they were difficult to observe visually after the season ended.

In 2019, 5/16” systems that received only new spouts (S) systems produced 10% more sap than 3/16” (S) systems.

Systems that received] new drops (D) produced 21% more sap on 5/16” systems, and 23% more in 3/16” systems. While this again represents an improvement for 3/16” systems, the gain is not as large as expected based upon the anticipated improvement due to natural vacuum.

When sanitized with bleach however, 5/16” lines again showed a 21% improvement in sap yield, matching the increases observed (and expected) with drop replacement.

In 3/16” systems, bleach sanitization increased sap yield by 53%, which slightly surpasses the predicted gain in sap yield.

This result is a strong indication that plugging of fittings is indeed the primary factor impacting yields in 3/16” tubing systems as they age.

It is likely that these plugs develop and grow, they greatly increase friction in the lines, and slow or stop the flow of sap, especially in the latter half of each sap flow season.

The fact that new spouts, check-valve spouts, and to some degree, new drops do not appear to result in the complete restoration of high sap yields in 3/16” tubing is a good indication that the typical recommendations for sanitation developed for 5/16” tubing systems are not entirely appropriate for 3/16” tubing systems.

The approaches developed for 5/16” systems were not designed to prevent or ameliorate the plugging issues observed in 3/16” systems; new spout or new check-valve spout doesn’t have any effect on a plug further downstream.

Similarly, a new drop (including the tee) doesn’t eliminate plugs in connectors/unions. Therefore, while these approaches will affect sanitation levels at the taphole, they cannot totally eliminate plugging.

These results are consistent with those observed in experiments by Cornell researchers, who have also reported success in 2019 trials with sanitation treatments in 3/16” systems in which tees were replaced. (Childs 2019).

Cleaning with bleach (in this instance a calcium-based hypochlorite solution) was used by a sugarmaker (Arthur Krueger) in southern Vermont, reportedly with excellent results as described in a Maple News article earlier this year (Krueger 2019).

Summary:

Sanitation is important in both 5/16” and 3/16” tubing systems, however these two systems have very large differences in how microbes affect sap yields over time, therefore the strategies to less this negative influence, and management to achieve adequate sanitation conditions are not the same.

A great deal of research-based information is available on sanitation of 5/16” systems – far less is known about sanitation of 3/16” systems. Based upon our results, it is recommended that maple producers using 3/16” tubing systems consider two possible options for sanitizing 3/16” maple tubing:

- Cleaning with a solution of calcium or sodium hypochlorite, preferably in the fall after the weather has gotten colder (to reduce recolonization and regrowth of microbes). It is important that an adequate amount of contact time is provided, 5-10 minutes or longer is preferred (this is typically not achieved when sucking in sanitizing solution under vacuum). Note that some new formulations of Clorox are not approved for certified organic maple operations. Also, to avoid a “salt” off-flavor, lines should be flushed with potable water after cleaning, or the first run of sap allowed to flow on the ground.

- Replace all 3/16” tees and 3/16” connectors at least every 2-3 years.

While there is some cost involved with either approach, it is anticipated that the gain in sap as a result of these activities will produce an adequate net profit to offset this.

Unfortunately the use of chlorine solutions may lead to the problem of squirrels chewing on lines. More work on the economics of sanitation approaches for 3/16” tubing systems remains to be completed.

Acknowledgements:

Funding was provided by the UVM Agricultural Experiment Station. The field assistance of Wade Bosley, Brendan Haynes, and Brian Stowe is greatly appreciated.

Literature Cited:

Childs, S.L. 2019. It could be the T’s. The Maple News. June 27.

Krueger, A. 2019. Sugarmaker weighs in on cleaning 3/16” tubing. The Maple News. Aug 4.

Perkins, T.D., A.K. van den Berg, and S.L. Childs. 2019. A decade of spout and tubing sanitation research summarized. The Maple Syrup Digest (in press).

Wilmot, T. 2018. Strategies for maintaining high sap yields with 3/16” tubing. The Maple News. Aug 3.