Tapping & Tubing

The Take Down Master

Tony Van Glad and family hit the woods to remove miles of tubing

By PETER GREGG | APRIL 2017

GILBOA, N.Y.—It’s hard to believe Tony Van Glad is still smiling.

Van Glad, a 6,300-tap producer in the Catskills region of New York, is one of the few sugarmakers who put up and then take down their entire pipeline system every season.

And during tour for The Maple News in 2014, in the middle of the “take-down” part of his season, Van Glad had a smile on his face and seemed even jovial as he coiled up roll after roll of lateral lines.

Sure, there are sugarmakers here and there that subscribe to the seasonal tubing program. But usually in random sugarbushes where the leaseholder insists on seeing no blue in their woods during warm weather months.

For Van Glad, every one of the dozen lease deals he has set up for his operation includes this provision. And he’s fine with it.

“It keeps everybody happy,” Van Glad says.

He’s been doing it this way since starting the operation in 1983. All of his leases are handshake deals and he says the landowners appreciate being able to access and enjoy their woods for recreation and to cut firewood.

He hasn’t lost a lease yet.

There are other advantages too. Van Glad can work on the system in the winter months—replacing fittings and drop lines and such—from the heated comfort of his barn, rather than the freezing mid-winter cold.

Also, squirrel damage is kept to a minimum since the window of opportunity for them to chew is short.

“If you leave it up all year, squirrels have 365 days to get at it,” Van Glad said. “This way they only have about 90.”

Every year, “after sobering up from New Year’s eve,” Van Glad and his wife Mary, along with their two sons, hit the woods and start stringing up the pipeline. Miles and miles of it.

Some of the woods are nearby the home farm. Other bushes are as far as ten miles away.

In all, Van Glad says it takes about four to six weeks to get everything ready for the season and start boiling.

Then after getting through the season — which this year ended in mid-April in 2014 — Van Glad and family are back in the woods, snipping and rolling and tagging the entire system. The whole thing will be down before the trees are foliated.

“We don’t fool around,” he said. “We want to be done with it.”

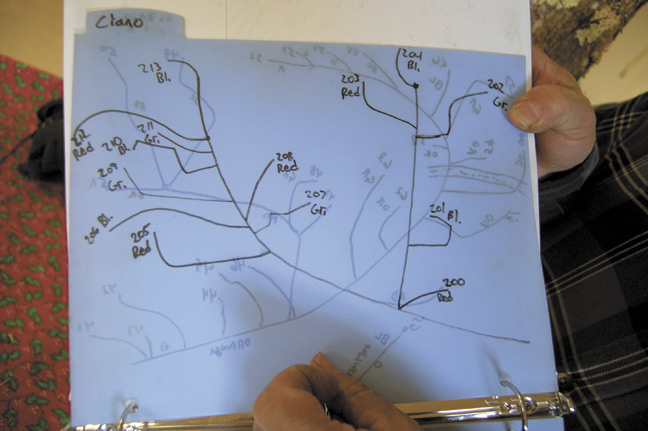

There is a method to his madness. Van Glad has about 10 binders full of intricate maps and notes on where exactly to put the tubing back next season.

He uses color coding system and spray paints the trees with red, green and blue blazes that alternate on the side of the tree that the tubing should run. He even paints horizontal lines on the tree to show exactly where the tubing should line up. Mainline runs along trees marked with “M.”

“It’s pretty much moron proof,” Van Glad joked.

Originally published June 2014