Candy & Cream

Sugarmakers offer tips on making granulated sugar and maple cream

Lake Erie Maple Expo speakers help fellow sugarmakers make the product right

By PETER GREGG | APRIL 29, 2020

MIDDLEFIELD, Ohio—James Miller is well known in the Buckeye State for high production and quality value-added products.

Miller offered tips on making good granulated sugar at the Lake Erie Maple Expo last fall in Albion, Pa.

“Sugar is probably the easiest and the funnest to do,” Miller said.

The most important thing is to get the temperatures right.

Miller says he shoots for between 255 degrees and 265 degrees F for making a sugar with a lot of “creep.”

Creep is the term confectioners use for describing how a pile of granulated sugar with the proper amount of moisture will move, if it’s piled on top of itself.

“You get a better creep at 255 to 260,” he said. “In a contest you get points for creep.”

If you are making sugar to use in cotton candy you should go to a higher temperature like 275 degrees to get a more dry finished product, Miller said.

He advised to make sugar as soon as the heated syrup leaves the stovetop.

“Start stirring as quick as you can,” he said. “That’s the best time for sugar is right after boiling.”

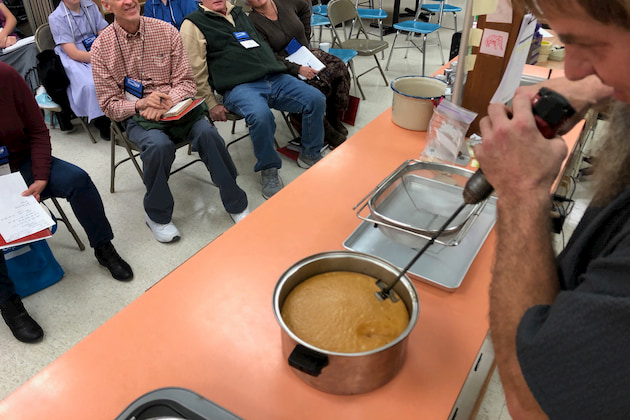

Miller demonstrated making good sugar with very few utensils.

He made an entire batch in a basic spaghetti pot and used an inexpensive paint stirrer drill bit from the local hardware store, making the ten minutes of stirring go easy.

Use a little defoamer to rim the pot before stirring, he said.

Meanwhile other sugarmakers shared tips on making good maple cream, another classic maple moneymaker.

Sugarmaker Jake Moser of 2,000-tap Moser’s Maple in Croghan, N.Y. recommends making maple cream using a gear-pump driven cream machine.

Moser’s operation makes 80 percent of its syrup into value added products, he said.

Maple cream is a big seller but can be tricky.

“Maple cream is one of the easiest but also one of the most finicky products to make,” Moser said. “It can be finicky getting a consistent product out the door that you’re proud of.”

Make sure the cream stays cold before it hits the machine.

“The cooler you start stirring the smaller the crystals,” Moser said.

He advises to boil it to 22 to 24 degrees F above the boiling point of water and then dramatically cool it down before running it in the machine.

Moser had it down to 110 degrees when it went through the machine during a demonstration at the Expo.

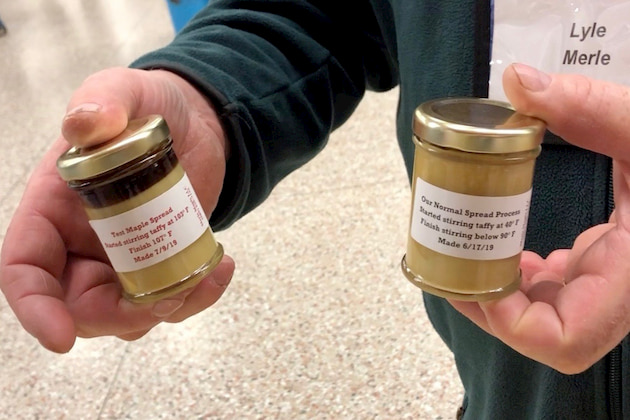

Lyle Merle of Merle Maple Farms in Attica, N.Y. shared his maple cream opinion, which were similar to Moser.

Stirring at the right temperature is key, he says.

Stir it when it’s cold. There is a noticeable difference in separation, typically 40 degrees for his batches.

“You need to keep it cold,” Merle said.

He also advocates for gear pump machines with a lot of HP if possible, up to 2hp.

The more horsepower, the less heat.

“The bigger the gear pump the better,” he said.