Sap & Syrup

Sugarmakers encouraged to check hydrometers this season

UVM Extension reports a nearly 1 in 4 failure rate for density

By PETER GREGG | FEBRUARY 21, 2024

MORRISVILLE, Vt.—Check your hydrometers!

Sugarmakers are encouraged to check hydrometers or make sure new hydrometers have been certified by the Vermont Department of Agriculture.

A recent survey by the University of Vermont Extension Service found that many syrups bought online were out of density compliance.

Extension agents bought online a total of 166 samples in 2021 and 182 samples in 2023.

Nearly 1 in 4 containers (22%) failed to meet the minimum density standard (66.9 ⁰Brix) for pure maple syrup, UVM Ext. reported.

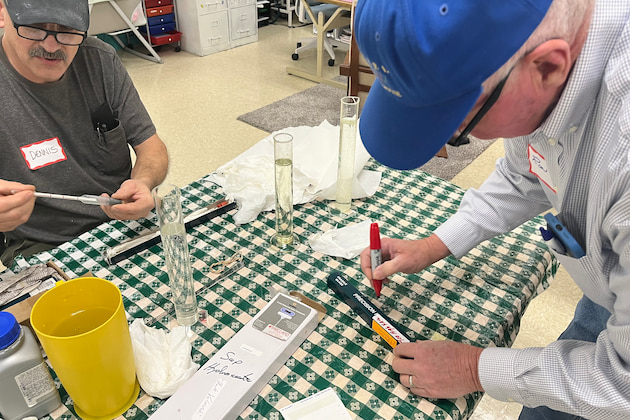

Many state maple associations or departments of agriculture offer hydrometer testing.

At a clinic in Connecticut last month, 5 hydrometers failed out of approximately 25 tested.

The federal standards for Grade A pure maple syrup in the U.S. require syrup to be no less than 66 ⁰Brix and no more than 68.9 ⁰Brix.

These density standards are shared across all states with grading regulations except for Vermont and New Hampshire which have a slightly higher minimum density (66.9 ⁰Brix).

Best practices for consistent and accurate readings with a syrup hydrometer includes only using hydrometers that have been tested for accuracy by a certified lab or trained individual with the appropriate equipment.

It is also good practice to have multiple hydrometers on hand to check when issues arise and to take multiple measurements, UVM Extension advises.

It's also critical to have precise and accurate measurements of syrup temperature, preferably from a hydrometer cup.

Cold hydrometers, dirty hydrometers and hydrometers with broken or damaged glass can all lead to inaccurate measurements.

Generally, anything that artificially adds mass to the hydrometer (calcium buildup, encrusted sugar, moisture soaked paper from cracked glass, etc.) will result in the hydrometer floating lower than it would otherwise, UVM Extension said.

This in turn could cause a sugarmaker to believe the syrup is less concentrated than it really is and would make syrup that is above the legal limit for syrup density.

If syrup is colder than the sugarmaker believes (211 ⁰F at the “Hot Test Line” for example) the colder syrup will be able to hold the hydrometer higher than at the warmer syrup temperature.

This makes the syrup appear to be more dense than it actually is and the producer could end up packaging syrup below the legal standard for pure maple syrup, UVM Extension said.