Sugarbush Management

Opinion: How is sugaring like dairy farming?

In up markets and down, we just add

By DAVID FOLINO | MAY 2017

I live and sugar in Addison County Vermont. In my area there are plenty of dairy farmers and plenty of sugar makers. I have quite a few friends who are dairy farmers and I am familiar with the business. I’ve watched the price of milk fluctuate dramatically over the past four decades, and during that time, I’ve watched dairy farmers use a strategy which seemed counterproductive and doomed to failure.

When dairy prices are high, most dairy farmers, whenever possible, add cows to take advantage of the increased price. And, when the price drops, they frequently add more cows to make more milk to pay the bills. Each side of the cycle drives increased milk production, and every round of low and high prices pushes farmers toward bigger farms with larger herds and supposedly greater economies of scale, but more debt.

There are obvious differences between the two crops, of course, such as the fact that milk is highly perishable until converted into butter or cheese, and the fact that maple quality and yields are still highly weather dependent, and the fact that maple is much less of a world commodity. But, recently I’ve begun to worry that maple producers may be falling into the same trap.

In up markets and down we just keep adding more taps. Sugar makers should not consider themselves to be immune from the laws of economics. It’s my feeling that this economic trap could be avoided if we start to think more about maple marketing and promotion.

When I started sugaring in Addison County in 1979 most sugaring operations were small. A large Sugarbush had 5000 taps. Sugaring income was supplemental. Sugaring debt load was low, largely because sugaring equipment was still basic and vitrually unchanged for almost a century. Syrup yields were almost entirely dependent upon the weather. At the end of the season you either praised or cursed mother nature and your strong or weak back.

Over the next 10 or 15 years we bumbled along and gradually figured out the best ways to use tubing, vacuum and reverse osmosis. Efficient and productive tubing systems began to appear and were replicated. Better vacuum pumps were installed. A few producers even achieved 20 inches of vacuum at the sugarhouse. Reverse osmosis systems were adapted and refined specifically for maple sap. As a result, maple production gradually increased and became more reliable. Bad years became less bad. Average years became good. Good years became very good. We were refining all of these new technologies and figuring out how to use them. In retrospect, the foundation was being laid for future growth. We were figuring out how to insure good crops in most years.

Right around the turn-of-the-century growth accelerated. In Addison County, throughout Vermont and in most of the maple region, tap numbers began to increase rapidly and technological innovations amplified the productivity of each new tap. But, very importantly, the market for pure maple syrup seem to be growing at roughly the same rate as production. Productivity expansion was approximately equal to market expansion.

Then in 2008 we had a poor worldwide maple crop. Market supply didn’t meet market demand. Prices spiked. Four dollars a pound for anything. Irrational exuberance followed. Expansion soared---and hasn’t really slowed down since. Maple conferences focused almost exclusively on how to produce more syrup. While the maple equipment manufacturers, aided by efficiency grant money, steadily cheered on the rampant growth. By the spring of 2016 the number of taps in Addison County had grown about 1200% since 1980. From Indiana to Maine maple production surged. Importantly, the average size and indebtedness of sugaring operations also increased substantially. A large Sugarbush now has 50,000 taps. Many producers are in a position where they need to make substantial loan repayments ---and when prices go down, it’s tempting to add more taps. A recent study put the average cost of a new 10,000 tap sugaring operation, excluding real estate, at $450,000. There is now more of an economic urgency to make more syrup.

Sugar makers are very resourceful and incredible innovators and risk takers, they are rapid adopters of new techniques and technology. They should be proud of how rapidly they have grown their industry, but they should also be wary of rampant growth that exceeds market demand. The economics of supply and demand are not a straight line. A 5% shortage does not imply a 10% increase in prices and a prolonged 10% surplus does not correspond to a price drop. Prices swing much further than that, even without the Canadian dollar entered into the equation.

Prior to the 2016 season, market and production equilibrium were still close. New markets and new maple products were being developed. More syrup was selling in more places every year. There was a little too much syrup, but not a huge surplus. So far, maple has been one of the few reliable, steady, profitable sectors of agriculture in Vermont. I fear that could change. The exceptionally good sugaring season of 2016 in Vermont and Québec was an example of how much we have expanded our production capacity. It demonstrated the combined effect of high tap numbers, high tap efficiency and good sugaring weather. I realize one good season doesn’t necessarily mean that we are going to be in a new age of over production. But, I believe we are very likely to experience repeated surpluses unless we change and re-balance our focus . The techniques which were pioneered in the 70s and 80s have now been refined and replicated. We think and talk about how to make syrup. We seldom talk about the necessity of broadening or support market development. So far we’ve been shielded from the full impact and volatility of a free market. The market has been stabilized and supported by the Québec Federation. At this point, the main reason for a reduction in bulk prices in the US has been a collapse of the Canadian dollar. What would happen if the Federation decided to open their dam because they had too much syrup in storage?

We need to shift gears. We now need to focus more on promoting and selling syrup. We need to restore and maintain the equilibrium between production and demand. Then, we need to fund maple promotion and fight for honest maple laws so that we are competing fairly with products that use maple on their packaging but not in their product. Nothing else will guarantee the long-term future growth and prosperity for the maple industry.

We have a big potential market that can be developed. Pure maple currently occupies a tiny slice of the sweetener market. This is not an argument against continued growth. This is an argument for balanced growth. If maple producers can be as resourceful and innovative in maple promotion and the fight for honest maple laws as they have been in maple production — we have plenty of room to continue to grow.

We can’t simply add more cows to work our way out of this situation. As I’m writing this, right now, once again, the cost of producing milk is greater than the milk check. Let’s not make that same mistake.

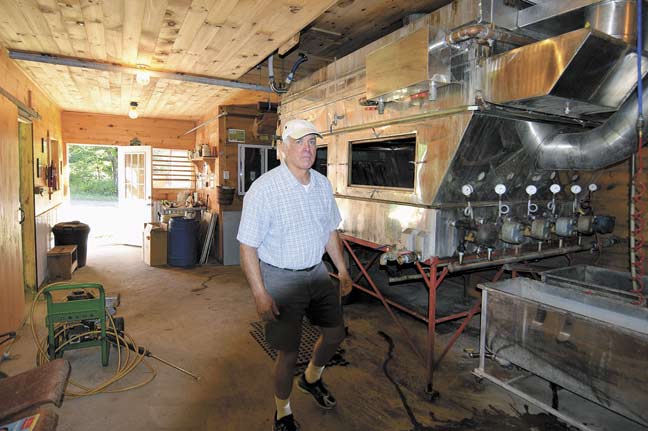

Dave Folino is a 15,000-tap sugarmaker in Starksboro, Vt. with his wife, Sue. Their Hillsboro Sugarworks has been operating since 1979.

Originally published in The Maple News in October 2016.