Sap & Syrup

More on bubbling sap

Sugarmaker Bob White in Vermont weighs in

By BOB WHITE | JULY 29, 2019

This season we tried bubbling raw sap on our farm in Underhill, Vt.

It appears we have only scratched the surface on understanding how maple flavors can be affected by our processes and the natural compounds and bacteria found in it (good or bad).

For years many of us have been focused on increasing per tap production and efficiency in the sugarhouse. However the old-time stronger maple flavors and darker syrups that commonly existed before the days of the R/O and high vacuum has since been elusive.

Our fellow producers in Canada have been working on aeration efforts for some time. They often struggle to get paid for some late season flavors so they’ve been motivated to look for solutions.

Bubbling clearly improved late season flavors. But the Canadians also found if the wrong compressor was used metallic off flavors could show up in the syrup.

So be careful or do not use a compressor at all if you try to bubble sap.

On our farm, we recently purchased a high-end oilless air compressor for our filter presses. When we first started using it, it put out some pinkish liquid in the catch jars. Now it puts out rust colored moisture when the tank is drained. Clearly it or any other compressor should not be used for aerating sap.

I believe the organic Canadian producers are no longer allowed to bubble sap or do any air injection. I’ve heard it said producers who used these methods felt they worked well. However there was a concern that some off flavors could reappear later in the long-term stored barrels. Not sure if it ever did or not. So again, there is a lot to learn and research needed.

We know of a second sap agitation type process that has been developed in Canada. We used it this year and were impressed with the results.

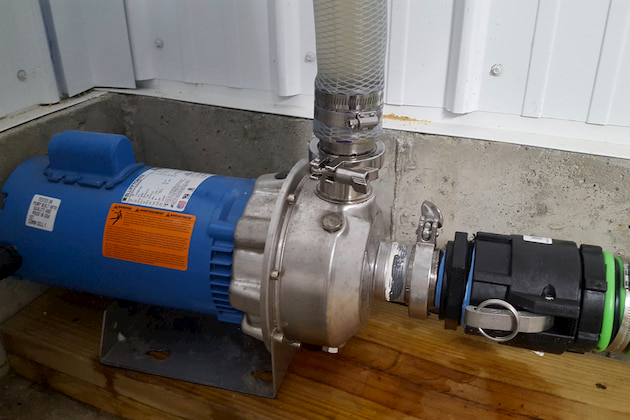

Vallier and Martin Chabot from CDL were kind enough to share the method with us. It was very easy to install and operate. It involves using a Gould SST pump to circulate and spray (Aerate) tanks of concentrate for approximately 12 hours to promote aerobic bacteria with dissolved oxygen. (Aeration of raw sap was not tried but likely should be).

Through trial and error, we found if too much pressure is used on the spray bar our whole tank room filled up with a sugar mist that coated everything. That was a hard lesson to learn.

The results were it improves the taste of good flavored syrup as well as poorer or off-flavored syrups. It worked that way for us this year.

Spraying for 48 hours darkened the color more and brought out a heavier flavor. It did not rope but did leave a thick layer of bacteria in the bottom of the tank. After that, we went back to only 12 hrs. Longer times may work better for late season sap if a chiller is used. We did not attempt to push the time with warm concentrate.

We also found that a massive amount of some of the strangest foul-tasting foam (we assume anaerobic bacteria) will form on the top of the tank. We shoveled it off with a snow shovel a few times then defoamed.

If you defoam you will need to ventilate your sap room with a fan to remove the smell. If not, the odor can settle back into the sap or concentrate.

In general, we made a little darker syrup with a flavor we were happy with.

Real end-of-season buddy flavor was not cured for us.

Metabolism was harder to detect after aeration but was still identifiable. Aerating raw sap longer might help this off flavor more.

We had very little niter build-up on our front pan. What did show up was easy to get off. Not sure if this will repeat in future years but it was nice.

For me, I tasted a flavor from our large Master evaporator that I remember my grandfather used to make 50 years ago when he made syrup on the kitchen stove and have not tasted since. Grandpa simmered down a pot then just kept adding more sap for a few days until he had enough syrup to make a small batch. Maybe a half gal or so. The result was a light colored very flavorful syrup.

There are more questions than answers in the flavor game. Clearly Mother Nature will remain in charge of flavor but here are a couple more thoughts:

—If sap is managed well, can high concentrate levels above 25 brix produce stronger maple flavor than the 18 brix commonly used today? Some who have tried this say yes. I assume there is a good potential to burn the back pan if it is pushed too far.

—I have heard it rumored that the Acer Center in Canada may have identified the bacteria that can promote or degrade desirable flavors. How can we use this? What potential things other than aeration can be done to help promote the good flavor bacteria over the bad bacteria?

—I also wonder if different colored tubing or types of pipe help or hurt, depending on how the sunlight and heat effects the sap in them?

—We have noticed stronger maple flavors and darker color in operations that truck sap in plastic tanks. Likely this is another form of aeration where the plastic holds enough bacteria to help the process.

Could we help flavor more by aeration in plastic tanks or is this just coincidental?