Sugarmaker Profiles

Masters of maple and mechanics

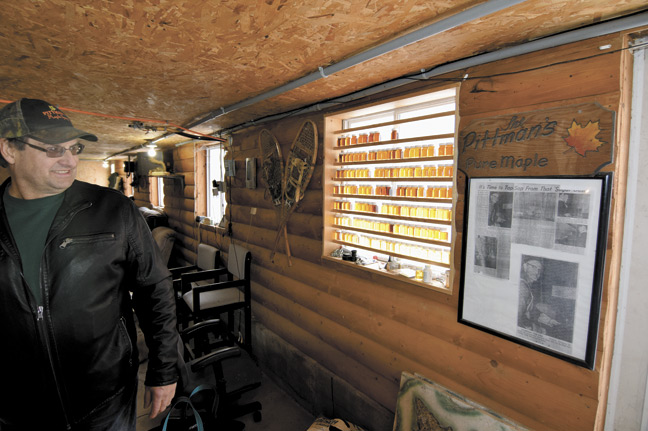

Wisconsin’s Pittman family experts at tinkering, and making good syrup

By PETER GREGG | FEBRUARY 2017

ARKANSAW, Wisc. — Sleep can be a precious commodity for Greg Pittman.

“Sometimes I’ll wake up at two in the morning with the solution to something I need to fix,” Pittman said. He keeps a pad and pen next to the bed.

He’s a tinkerer and has a gift for understanding out how things work just by looking at them. He’s a machine whisperer, so to speak. Same goes for his son and son-in-law, both tinkerers too. Wife Debbie keeps the whole operation humming and organized.

So a walk around the Pittman maple operation—started five generations ago in 1945 in southwest Wisconsin—will reveal evidence in barn after barn of the master tinkerer and his junior tinkerers at work.

The workshop for example, is more like a giant mechanical laboratory, where Pittman and son Jason, along with son-in-law Eric Maxwell, take apart and put back together pumps, old generators, old R/Os. Everything. There are fan belts everywhere and buckets of parts and nuts.

“You never know when you are going to need something,” Pittman said.

Or take a look in the second floor of the two-story sugarhouse. Pittman has devised a heat-reclaiming system that is so efficient, you can put your hand on the final exhaust that runs out the side of the building and it will be ice cold.

He captures every last degree of heat in a series of preheaters, saving tons in fuel. And he doesn’t have to worry about his old 30-foot stack blowing over anymore.

Everyone in the neighborhood likes to bring Pittman their old pumps. He’s guaranteed to get them working.

In the R/O room, Pittman has one of Leader Evaporator’s new Springtech Extreme R/Os, which he is very happy with. But he also has his first R/O, which he built himself, and will use as a backup when the season warrants.

Solving problems and making things run well are the family specialty, as their operation grows and grows.

The Pittmans boil off about 4,500 taps of their own, but they take in sap from upwards of 30 different producers in the area, both big and small.

During sugaring season, their big parking lot in front of the sugarhouse is full of idling pick up trucks with tanks full of sap.

“You don’t want to be around here during the hours between five and seven,” Pittman said “It’s just non stop with trucks rolling in here.”

Right now the family has a waiting list of other tappers in the area looking for a home for their sap.

“We can only do so much,” Pittman said.

But at the same time, they still find themselves taking in sap from everyone anyway.

“We don’t want to turn anyone down,” Jason Pittman said.

The Pittman’s are now expanding into equipment and supplies, carrying the full line of products from Leader Evaporator and Sugarhill jugs.

The store in Arkansaw is fully stocked and Leader will make regular deliveries there, making sure it is supplied throughout the season.

And the syrup side of the business is growing too. Most of their barrels are going to Steve Anderson of Anderson’s Maple Syrup in Cumberland, Wisc. But they are also wholesaling to high end restaurant accounts, particularly in nearby Chicago and Minneapolis, where top chefs love using their syrup in recipes.

The Pittmans advertise a preference for wood fired syrup.

They claim in a brochure that “high intense wood heat” is what makes their syrup taste so good. Whether it’s the wood, the reputable Wisconsin soils or general expertise, the family’s syrup is undeniably outstanding and delicious. And they plan to keep making more and more of it.

“It just keeps getting bigger,” Jason Pittman said.