Food Safety & Gov't Regulations

Lead equipment ban for small producers nears

Two deadlines in 2020 for California compliance

By PETER GREGG | FEBRUARY 20, 2020

ALSTEAD, N.H.—Last chance to get the lead out.

Small scale sugarmakers must have nearly all lead equipment out of the production process this season if they plan to sell their syrup to a bulk buyer. And all the rest of their lead equipmnet must be scrapped by October, the last wave of compliance with state of California regulators who sued syrup packers six years ago for not meeting that state's stringent lead-free standards.

“The industry needs to be compliant,” said Ray Bonenberg of Mapleside Sugar Bush in Pembroke, Ont. and past-president of the International Maple Syrup Institute which has been helping educate producers on the issue.

Sugarmakers with 10,000 taps or less must get even the smallest piece of lead-laced equipment out of the sugarhouse if they plan to sell any syrup to a wholesale buyer this spring.

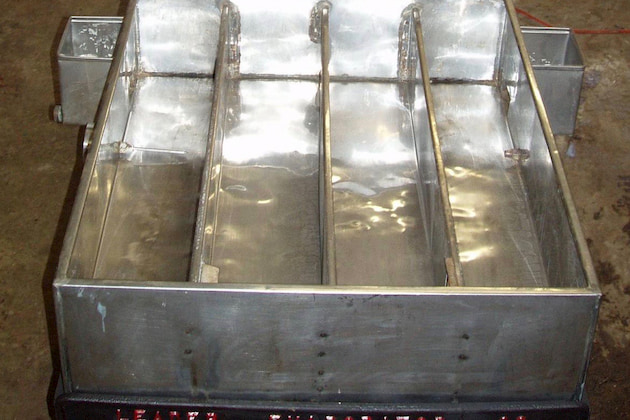

This season, they need to immediately remove valves, connectors, joint and level controls, pre-heaters, Piggy Backs and Steam Aways, syrup pumps, finishing stoves and evaporator pans if they plan on selling bulk syrup.

Again, the rule only applies to sugarmakers who plan on selling to bulk syrup buyers, or who live in states where a total lead ban is already in place.

They should have already eliminated sap buckets, galvanized sap tanks and old spiles from the their systems prior to this season, according to the settlement requirements.

They have until Oct. 1 to remove the last remaining sap pumps, filling units, filter tanks and filter units that may also contain lead.

Sugarmakers should pay attention to when their equipment was manufactured. If it was maple specific equipment like a syrup pan made pre-1992 it almost certainly has lead.

Some equipment makers used lead-free solder after that date and it is hard to eyeball lead vs. lead-free solder.

Large and medium scale producers should already be in complete compliance if they are selling to bulk buyers, according to the settlement guidelines.

“As an industry we want to have food that is safe,” Bonenberg said. “That is the ultimate message. We have moved through that with a progressive system that gave smaller producers time. Six years is reasonable.”

Bruce Bascom, one of the biggest bulk buyers in the U.S. and also an equipment dealer told The Maple News that his company has not been taking in any lead soldered equipment on trade for resale.

Bascom acknowledged that there is still some leaded equipment in use in the industry and that small scale producers are the last line of compliance.

“Most larger producers, where most bulk syrup comes, have removed leaded equipment, but the transition to all non-lead is not complete yet especially among smaller producers,” Bascom said.

Used equipment is actively swapped in the classifieds section of The Maple News, Craigslist and on MapleTrader, some of it almost certainly containing lead.

Laws vary from state to state and province to province on whether lead equipment can be used in any way in production, regardless of where the end product is sold.

For example, Ontario has banned all lead equipment from production. Meanwhile, the state of New York has no such law.

Lead is considered a dangerous carcinogenic and should never be used whether a sugarmaker is selling bulk or just making syrup for home use, industry leaders say.

If a producer has an old lead-soldered pan, it should be scrapped.

“You should take a bulldozer and drive it over that pan,” Bonenberg said.