Sap & Syrup

EcoVap electric evaporator catching on

Only 21 cents of fuel costs per gallon of syrup

By PETER GREGG |

MONTREAL — Dominion & Grimm's new evaporator technology, the EcoVap, makes making syrup as easy as turning on the dishwasher at night before you go to bed.

It runs on electricity. That’s right, electricity.

Now in its third season, D&Gs EcoVap keeps proving itself. It offers a massive cost savings to the producer.

"We have a sugarmaker in Northern Vermont that uses one and his fuel costs are 21 cents per gallon of syrup made," said D&G sales manager Benoit Pepin.

During a tour for The Maple News at Pepin's home sugarhouse in Notre Dame de la Merci, Que., we got to see the EcoVap churning, but silently and with not a wisp of steam in sight. The only evidence of syrup being made was the continuous draw draining into a draw-off tank.

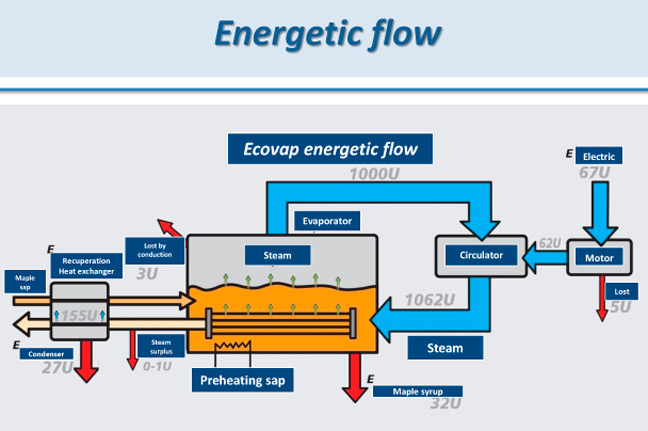

The unit is completely self-contained, recirculating and pressurizing the steam through coils immersed in the sap. Every degree of heat is kept within the machine. Nothing escapes.

The electricity is only used at the beginning of the boiling process and once it heats the sap, the pressurized steam takes over.

On this boiling day, with 7,000 gallons of sap in the tanks, one hired man was running everything, including the R/O and the evaporator and he still had enough time on his hands to wash pans and pack syrup.

“I cannot live without it,” said Alain Pelletier.

A touch screen on the side of the machine tells the user exactly how much in energy costs he is accumulating as he boils—approximately $4 per hour on smaller models, and $17 per hour on bigger one.

“It’s the first green machine on the market,” Pepin said, claiming that the rig leaves a zero-carbon footprint, at least in Quebec which gets its electricity from hydro-electric dams on Hudson Bay.

Pepin said other benefits come from the intangibles. It doesn’t require a roof jack, no splitting wood, no fuel tanks and no more dependency on fuel prices.

Pepin recommends that sugarmakers use 12 percent concentrate to run the EcoVap. D&G has used it as low as 10 percent and as high as 18. But they found 12 percent is best to ensure good flavor.

“We’re proud of what we’re making,” Pepin said of his syrup. “We’re making food. It should taste good.”

Pepin explained that in many ways, syrup-making technology has hit the maximum efficiency in terms of speed and effortlessness. That the path to more profitability in the sugarhouse is not by making more syrup faster, but by reducing expenses.

“There is only so much you can get from the tree,” he said.

Originally published June 2014. Updated April 2016.