Headlines

Don’t miss the 2017 Vermont Maplerama

Aug. 3-5 at the VFW in Hyde Park, Vt., 129 VFW Drive

By SLOAN BULLARD | JULY 20, 2017

Vermont Maplerama, the summer tour that features the showplace sugarhouses of Vermont is slated for Aug. 3-5. This year’s event is hosted by the Lamoille County Sugarmakers and will take place at the VFW in Hyde Park , Vt. The event includes tours, a trade show, banquet and awards ceremony, and a Saturday BBQ.

There are 14 sugarhouses participating in the tours on Saturday and Sunday ranging in size from 140 taps to 83,000 taps. The tours will also feature the 2016 Vermont Dairy Farm of the Year, a distillery, a winery, and the Butternut Mountain Farm production facility. Almost every town in Lamoille County is represented. Maplerama 2017 will also feature the latest technologies in evaporators with electric, steam, oil, and wood pellet as well as a couple of wood fired evaporators. New this year, a full day forestry clinic offered will focus on timber stand improvement in the sugarbush, invasive species management, and improving your roads and water crossing. Click on the following links for the schedule of events, tour descriptions and details, and the registration form.

Schedule of Events Maplerama 2017

Maplerama Registration form 2017

2017 Lamoille County Maplerama Tour Host Descriptions

For all event questions, please contact Arnie Piper at 802-888-9385 or arnoldpiper@comcast.net.

Here are the sugarhouses featured on this year’s tour:

Friday August 4th Tour “A” Hosts

Judevine Farm

Judevine Farm is a second generation family farm that has been in operation since 1970. Run by Andrew Naylor and his family they currently run a 13,200 tap sugarbush on their 200 acres of land. There is a fair amount of underground mainline in their sugarwoods and they also have a sap ladder with 40’ of vertical lift and maintains 11 inHg or higher on the mainline before the ladder. In the sugarhouse they have an oil fired 4’ x 16’ Lapierre Turbo II evaporator, a 6 post CDL RO and a 10 hp 2 stage Sihi vacuum pump. In the summer of 2016 Judevine Farm’s sugarwoods, along with many surrounding sugar bushes were, effected by Forest Tent Caterpillars and suffered serious defoliation. The Naylor’s plan to have their woods sprayed for the caterpillars in the May 2017. In the off season of maple production they also have a firewood processer where they process around 200 cords of dry firewood annually.

Corse Family Maple

Corse Family Maple started in 1998. At the time they were only a 12’ x 12’ sugarhouse with a 2’ x 6’ evaporator inside where they were boiling the “raw” sap from their 150 taps. Over the next few years they increased their tap count to 3,000 taps and also added the aid of a small RO. They continued to use the original sugarhouse and 2’ x 6’ evaporator for the 3,000 taps until 2015. The next season the Corse family built a new larger timber frame sugarhouse at a different location. They now have a 3’ x 12’ CDL oil fired evaporator, a 1,800 gallon CDL RO and a 2 stage Kinney vacuum pump. They also have 2 different pump houses that pump sap with one pumping sap 1,500’ over a ridge to the new sugarhouse location.

Marsh Family Sugarworks

Starting in 1909 with several hundred buckets and a small dairy farm, the Marsh family slowly grew their sugar place over several generations to 7,000 buckets. By the mid 80’s they had converted their woods over to 5/16” tubing and had decided to sell their dairy operation and go full into maple. The Marsh’s rented a neighboring woods and became the second largest sugaring operation in the state of Vermont and used the newest technology at the time to help them process the large volume of sap in the original sugarhouse. They sold their old wood evaporator for an oil fired one and using an RO (one of only two in the town at the time). Since then the Marsh’s have scaled back their sugaring operation and tap only woods that they own. They have just under 11,000 taps over a 183 acre woods and still tapping some of the original maples from the starting sugar place. The sugaring operation is now owned by Rick Marsh and his wife Diane and their son Ryan helps them run it. Rick and Ryan are the fifth and sixth generations to produce maple syrup from this sugar woods and take pride in being so and are in hopes the seventh generation, though young now, will be a growing part of it in the near future. The original sugarhouse had been replaced and the sugarwoods has been set up with a “state-of-the-art” high vacuum 5/16” tubing system and is run with a 7.5 hp Air-Tec rotary craw vacuum pump. During the 2016 maple season the Marsh’s installed CDL’s monitoring system throughout their entire woods to help them increase production and to help them save on time and labor in the woods. In their sugarhouse they have 13,400 gallons of rap storage that is in a below ground level insulated room that allows for sap to be held and not freeze in the tank during cold early season runs and it helps to cool the sap during the hot late season runs. They have a 20+ CDL RO with 1 – 16” membrane and 4 – 8” membranes that is used to process the sap at a rate of over 4,000 GPH to 20 - 22 brix in one pass. After the 2016 season them Marsh’s installed a new 4’ x 15’ oil fired CDL Master evaporator to help with speed and efficiency and during the 2017 season they were using 0.22 gallons of fuel to produce 1 gallon with the new evaporator. As part of this tour stop the Marsh’s will be doing a demonstration of their monitoring system on how it works, the added benefits to having a system like this in your sugarwoods and what they have learned with using the monitoring system in their woods for two seasons.

Boyden Valley Winery/

Boyden Sugarhouse

The Boyden Valley Winery is located in a restored 1875 carriage barn on the Boyden family farm. Boyden Valley Winery is steeped in the culture and agricultural heritage of Vermont’s Green Mountains. From 8,000 grapevines and 100 acres of maple trees, lovingly tended by their family for four generations, they craft wines that feature only the finest locally grown fruit from the loamy soils of the Lamoille River Valley. All of the wines are fermented in temperature controlled stainless steel tanks to produce elegant, lively whites and medium bodied reds full with character. Aged in time-honored French Oak casks, our cellars to yield mature European style wines. The Boyden family taps are on pipeline and vacuum. After the sap is ran through the RO it is boiled on a 6’ x 18’ wood fired evaporator with a steam pan. Much of the maple syrup produced on the farm is sold in their retail shop or used to produce their craft distilled cream liqueurs. Boyden Valley Spirits is proud to be the first craft distilled company in the U.S. to specialize in cream liqueurs. Started in 2010, our craft distilled cream liqueurs are made in Vermont using Vermont grown apples and their own maple syrup.

Putnam Maple

Putnam Maple is owned By Bill Putnam and located in Cambridge. The Putnam Family purchased the farm property in 1854 and to the best of their knowledge this sugarbush has been in production ever since. Their new sugarhouse was built in 2002 and is the 5th one that has been on this property. The original sugar house was in use until Bill’s Father built a new one in 1936. It sat not more than 300 feet from where their current sugarhouse sits. The story is that the building was in use down on the farm across the road and was moved up for use as a sugarhouse by 15 teams of oxen and was moved non-stop from the old site to the new site. The 1936 building served well until a clear July night in 1968 when it and all the equipment burned to the ground. The next sugarhouse was for a small 3’ x 8’ arch and only a small number of trees were tapped as all the kids were in school and the farm did not have excess labor for sugaring. The larger bush was rented out for a few years and sap hauled off site. After Bill went to college and returned to the farm, they built a new building in 1976 and from 1979 through 2001 the Putnam’s combined operations with Boyden’s for a total size of about 6,000 taps. Now the Putnam’s process just their own 3,650 taps. All their trees are now on tubbing and they have a 5 hp Sihi water cooled vacuum pump to run 24 – 25 inHg on their woods. They have a 3’ x 12’ wood fired Dominiom & Grimm evaporator. The evaporator has cross-flow front pans and forced air in the firebox. They also have a CDL 1200 GPM RO and concentrate to 12-15 brix. .

Runamok Maple

Owned by Eric & Laura Sorkin, Runamok Maple has been in operation at their Cambridge sugarhouse since 2009. With the 83,000 taps that they manage and process it easily puts them with in the top 5 largest maple producers in the state of Vermont. The original sugarwoods is 72,000 taps that all run directly to the sugarhouse, making it one of the largest amount of taps to all flow into one place in the state. They have also have an 11,000 tap sugarwoods in Fairfield. The sap from this sugarwoods is run through an RO and concentrated before that is hauled by truck to the Cambridge sugarhouse. Between the two woods their 83,000 taps cover over 1,300 acres and they use 6 – 10 hp Sihi liquid ring vacuum pumps to keep their vacuum high. At the sugarhouse they have 10 – 6,700 gallon stainless steel tanks for storage before it is ran through their two ROs. Each RO is a CDL 20+ RO with 2 – 16” membranes and 6 – 8” membranes. Concentrated sap is processed on two 6’ x 10’ stream evaporators. The evaporators are powered by a 400 hp steam boiler that produces roughly 13,000,000 BTU/hour. Each year they process around 45,000 gallons of maple syrup off these two evaporators. Besides for their pure maple syrup, Runamok Maple is making and offering a line of barrel-aged, infused and smoked maple syrups and you can check them out at runamokmaple.com.

Friday August 4th Tour “B” Hosts

Lanphear Family Farm

The Lanphear Family Farm is a 500 cow Holstein dairy located in Hyde Park. It was recently named the 2016 Vermont Dairy Farm of the Year and was recognized for its well-managed herd, high quality milk production, sound management practices and strong work ethics. The farm is now owned by Kirk & Katrina Lanphear but it was originally started by Kirk’s parents in 1960. In 1999 they started the construction of the new dairy facility and it was completed by 2003. Each year the Lanphear’s farm the 700 acres that they own with an additional 300 acres that they rent to make enough high quality feed that they need for their cows. They milk their cows twice a day and produce enough milk to fill a tractor-trailer tanker full of milk every other day. The large free stall barn is equipped with alley scrapers that continually clean the barn floors 10 times a day and the stalls have mattresses for the cows to lay on for extra cow comfort. Between the daily farm chores and averaging a new calf being born every 12 hours they have utilized technology to aid them. They now have over 40 different computers that control automation in the barn along with cameras though out the barn that can be viewed anywhere through the internet.

Butternut Mountain Farm

Local farmers have been selling their maple syrup to the Marvin family of Butternut Mountain Farm for forty years. Butternut Mountain Farm in Morrisville, Vermont is one of the largest maple processors and distributors in the United States. Their team of ninety plus employees steward maple syrup’s transformative journey from local trees to food ingredient manufacturers, distributors, retailers and consumers worldwide. Butternut Mountain Farm produces maple sugar, maple candy, and packages specialty maple syrup for their own line of maple products as well as for other retailers in their state of the art facility. The 75,000 sq ft production facility is certified organic, Kosher, and SQF. Following exacting production standards, they proudly track every barrel with rigorous quality control and advanced supply logistics to ensure they deliver great products, on time, every time to every class of customer, from mass-market retailers and multinational food manufacturers to chefs and individuals. The farmers with whom they work understand maple and share their commitment to maintaining the health and sustainability of our forests. Over the past forty years they’ve built relationships with approximately 350 select maple sugar makers - people whose stories they know and whose practices they respect. Even though the suppliers of Butternut Mountain Farm manage over 100,000 acres of land they can trace every drop of syrup from farm to table. The Marvin family also own and operate their own sugaring operation, Butternut Mountain Farm Home Farm. Located on a hillside 1,000 ft. above the village of Johnson at the end of three miles of rough dirt road is the 600 acre tree farm that the Marvin Family has stewarded for more than half a century. You can find out more at butternutmountainfarm.com.

Charlie Davis

Davis Family Farm is a small family operated farm specializing in raising grass feed beef cattle and are third generation sugarmakers. Owned by Charlie Davis and Tom & Jo-Anne Ring, they have 1,900 taps cover 15 acres located in Hyde Park. In the fall of 2003 they built a new sugarhouse and had their first boil in the new building in March of 2004. They have a 4’ x 16’ wood fired King evaporator with a rear preheater and use a small RO to help reduce the amount of boiling they would need to do to make their maple syrup. This season they added a new 3 hp vacuum pump and a new 1,800 tank for sap storage. Friend and family are always welcome at the Davis Hill Farm sugarhouse and two to three times each year they will host a pot luck meal will all of them at the sugarhouse and enjoy good food and fresh maple syrup.

Cold Ridge Maple, LLC

Cold Ridge Maple, LLC is a fairly new sugaring operation, but the owner Aaron Boissoneault has been helping other family members make maple syrup for years. In the fall of 2014 they started to run 5/16” tubbing through his 122 acre sugarbush to make the 5,000 tap operation that they have today. They had their first full maple season the next year in 2015 and began to make maple syrup in their new sugarhouse. Cold Ridge Maple has a 3.5’ x 13’ oil fired CDL evaporator, a CDL RO with 5 – 8” post, 9,600 gallons of sap storage and a 7.5 hp CDL vacuum pump. The operation became “Certified Organic” during the 2016 season by Vermont Organic Farmers, LLC.

Darkwing Maples

Darkwing Maples located in Wolcott began their sugaring operation in 2014 when they purchased a piece of property that had a 3 year old sugarbush on it. The 8,500 tap sugarbush was a “turn key” with the tubbing already installed and with an existing sugarhouse and evaporator. Since 2014, in addition to their own land, Darkwing Maples has grown its sugaring operation and leases two other sugar bushes, while also purchasing sap from neighboring sugarwoods. They now boil the sap for 19,500 taps on their 4’ x 15’ CDL evaporator with a steam pan and have a H2O Super Six RO help cut down the boiling time. They also have a 10hp Kinney Vacuum Pump and 7.5 hp Bush Vacuum Pump to keep tight vacuum over their woods.

The Elmore Sugarhouse

The Elmore Sugarhouse is located near the picturesque Lake Elmore. Previously “Joslyn Maple Products”, Michael Boudreau purchased the property in 1989. He ran the operation and eventually expanded with the purchase of additional land. Michael developed a vast mail order business of retail maple syrup and other maple products. Eventually the maple business had to take a back seat to his “real” job and the facility went to a reduced production and then eventually to just selling the sap from his sugarwoods. In 2011, Michael hired Caleb Suddaby as a seasonal employee to work the woods tapping and doing the repairs. They continued selling sap for a few more years until 2014 when they changed and started to boil their own sap again. Now as full time “Operations Manager” Caleb, with the help of other manage and boil all the sap from their 9,500 taps that cover the two properties and in the plans to expand onto a third property for 2018. In the sugarhouse they have a 2004 5’ x 15’ oil fired Lapierre Volcan with a Leader “Steam-Away”, a 2016 CDL 20+ RO with 1-16” post and 3-8” posts.

Green Mountain Distillers

Green Mountain Distillers is a craft-distiller located in a newly opened state of that rat facility in Morrisville, Vermont. Since 2002, Timothy Danahy and Harold Faircloth III, the Founders and Master Distillers, have dedicated themselves to producing handcrafted, organic distilled spirits. All of the Green Mountain Organic products are meticulously crafted, using small-batch fermentation and a propriety distillation process. This process has been Certified Organic by Vermont Organic Farmers, one of the nation’s oldest and most prestigious certifying agencies, as well as the USDA National Organic Program. The Green Mountain Distillers method guarantees premium quality and exceptional taste. Every Green Mountain Organic products begins with the highest quality, 100% Certified Organic gran, provided by a family farmer- owned cooperative. These farms use only chemical free compost, clean water and the care and attention that is required for organic goods. There are no genetically modified organisms (GMO’s), synthetic pesticides or chemical fertilizers used in the farming process. After harvesting, the grain is packed and shipped in triple walled, recycled bags. Once at the distillery, the grain is combined with Vermont spring water, drawn from a source located close to Mount Mansfield, the tallest peak in Vermont. This is then distilled six times to produce the highest quality spirits possible. The six time distillation process results in the purest of spirits, with no need for exotic filtrations.

Friday August 4th Tour “C” Host

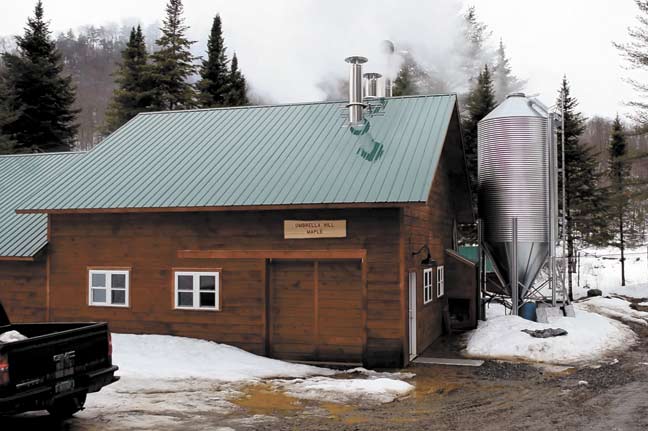

Umbrella Hill Maple

Two old college friends, Mike Macy and Arnie Piper started their sugaring operation in 2014 on land purchased in Hyde Park adjacent to the Green River Reservoir by Arnie and Beth Piper in 1996. Arnie had retired from the US Army and Mike had a career change allowing for Mike to be flexible enough to sugar. They apprenticed for a year with a good friend who mentoring them on everything maple and they jumped in with both feet with 7,000 taps in the first year and expanding the next year to 10,700. They learned by doing and listening to other sugar makers and friends who all seem to give great advice. Although not experts they’ve learned to make great maple syrup. This sugarhouse is completely off the grid and is run by a generator. They have a 4’ x 14’ CDL wood pellet evaporator that is fed by a 20 ton silo, 1,200 gallon per hour CDL RO, 10 HP Vacuum Pump and a 16” x 24’ pump station in the woods that pumps 5,000 taps almost a mile to the sugarhouse.

This sugarhouse will not be a normal tour stop. Umbrella Hill Maple will host a day long series of hands-on forestry related clinics led by Vermont County Foresters. The clinics will include timber stand improvement of a sugarbush, how to identify and eliminate invasive plants in your sugarbush, and how to improve your roads and water crossings. This clinic will be limited to 20 participants. If you wish to participate in this clinic wear appropriate clothing for walking and working in the woods.

Saturday August 5th Tour “A” Hosts

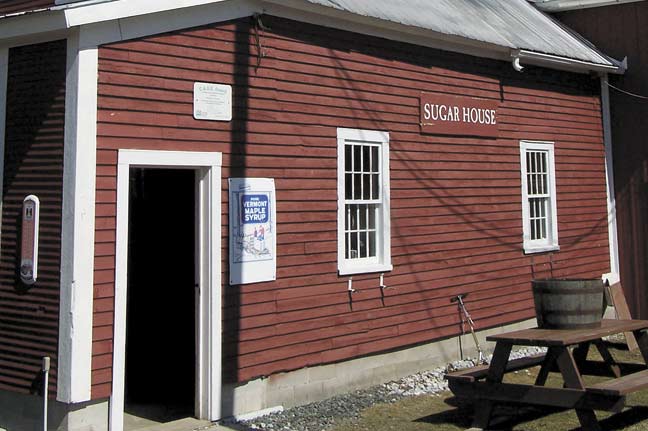

Cook’s Sugarhouse

Cook’s Sugarhouse is located in Hyde Park. Sitting on 2 acres the new 10’x12’ sugarhouse with an attached sap storage shed was built in 1989 after sugaring for 2 years in a rustic lean-to. They began their family business with only 50 buckets and since then have grown to 140 taps with all but 8 buckets on 3/16” tubing, 60% of which is on vacuum. The vacuum system is Sap Puller single 5” diaphragm pump, pulling 25 inHg at the sugarhouse, topping out at 27 - 28.5 inHg at the top of the lines. The 3/16” tubing lines on gravity still that they have pull 20 – 24 inHg. An annual crop for them is producing between 40 - 50 gallons of maple syrup, though 2016 the made 56 gallons or .4 gall/tap. The Cook’s continue to gather their tanks with their John Deere tractor and their children, now grown, grew up learning how syrup was made and helped in our sugaring operation.

Maple Sugar Mountain, LLC

Maple Sugar Mountain is a family owned and operated business located in Belvidere. Their business is built on the values and work ethic of generations of home-grown Vermonters, producing 100% pure Vermont Maple Syrup. A family owned and operated business, Maple Sugar Mountain, LLC is dedicated to producing the finest organic/kosher maple syrup the Green Mountains can provide. The family taps the trees, maintains the woods and boils the sap they collect into delicious maple syrup. The just over 19,000 tap sugarbush is located on over 415 acres of family land, once used for fishing, hunting and family recreation and forest management has been a top priority over the years. This sugaring operation has only been active for the past 5 years but prior to that the operation was located on the family homestead in Waterville. Maple Sugar Mountain, LLC uses an electric evaporator instead of more common wood fired or oil fired. The steam heat from the electric evaporator assures the syrup is boiled evenly, resulting in the highest two grades in the maple syrup market.

Burnor Family Maple

Burnor Family Maple is a fourth generation operation. It initially began as a family farm in 1806 under the Warren family name. The family sugar house, built in 1914 still stands today in the sugar woods. In the 1950’s the family had a successful mail order operation until 1962. After a 25 year hiatus, they began their passion for sugaring once again under Burnor Family Maple. The Burnor family built a new modern sugar house in 2005 and have a 3’ x 12’ Lapierre evaporator, a 600 CDL RO and a 5 hp Sihi vacuum pump. Today they make approximately 600 gallons of maple syrup annually from their 1,700 tap sugarbush that spans over 50 acres of land located in Eden.

Elmer Durvage

(Sap location)

Saturday August 5th Tour “B” Hosts

Cook’s Sugarhouse

Cook’s Sugarhouse located in Hyde Park. Sitting on 2 acres the new 10’x12’ sugarhouse with an attached sap storage shed was built in 1989 after sugaring for 2 years in a rustic lean-to. They began their family business with only 50 buckets and since then have grown to 140 taps with all but 8 buckets on 3/16” tubing, 60% of which is on vacuum. The vacuum system is Sap Puller single 5” diaphragm pump, pulling 25 inHg at the sugarhouse, topping out at 27 - 28.5 inHg at the top of the lines. The 3/16” tubing lines on gravity still that they have pull 20 – 24 inHg. An annual crop for them is producing between 40 - 50 gallons of maple syrup, though 2016 the made 56 gallons or .4 gall/tap. The Cook’s continue to gather their tanks with their John Deere tractor and their children, now grown, grew up learning how syrup was made and helped in our sugaring operation.

Sullivan Family Farm

The Sullivan Family Farm in Johnson has been in the Sullivan family for approximately 60 years. Over the years the family farm has been a dairy farm, raise beef cows, horses, chickens, and pigs and recently added a maple sugaring operation. The family has been running the sugaring operation on the farm the past 8 years. The Sullivan family has been operating their 4,500 tap sugarbush on their 75 acres and continue to grow in size each year. The Sullivan’s sugarhouse is a renovated historic dairy barn where they have a 3.5’ x 12’ CDL Deluxe oil fired evaporator, a Kingdom RO with 3 – 8” membranes, MES releaser with well pumps and a 7.5 hp CDL Air-Tec liquid ring vacuum pump.