Sap & Syrup

Coated jugs make a difference in keeping grade

Proctor researchers examine syrup darkening in uncoated and XL-coated jugs

By T.D. PERKINS, W. BOSLEY, G. BOSLEY, AND M. MOORE | APRIL 6, 2020

UNDERHILL CTR., Vt.—Coated jugs can make a difference in preserving syrup grade.

Maple syrup is classified, in part, by the amount of light transmitted through a sample, ranging from 0100 percent transmittance compared to a glycerol control.

This is commonly referred to by maple producers and consumers as “color” or “grade.” The U.S. and Canada use a common classification scheme for maple syrup based on light transmittance.

Sap directly from maple trees is predominantly sucrose. Sap that has been stored for a period of time, particularly when it is warm, typically has a higher microbial load, which results in microbial inversion of some portion of sucrose into invert sugars (glucose and fructose).

Formation of color in maple syrup is due to a series of reactions in sap involving these invert sugars and other sap constituents and during caramelization reactions during boiling.

When syrup is reheated for packing into retail containers, light transmittance (LT) typically drops, mostly as a result of oxidation reactions.

This is very noticeable in widely-used HDPE plastic maple containers that have sat on the shelf for some time.

Certain plastic containers employ an externally applied polyvinylidene chloride copolymer (Hillside© "XL" coating) to reduce oxygen permeation through the container in order to reduce the rate of syrup darkening.

For regulatory purposes, it is important that syrup packed under a certain grade designation remain within the range of the grade until purchased by the consumer.

Syrup that falls below the LT for the grade range can be removed from sale, resulting in a significant loss of revenue. Slowing the rate of darkening helps sellers of maple syrup ensure that syrup packed at a specified grade will remain in that grade for a longer period of time.

Although several previous studies have examined syrup darkening in different retail containers, packers and producers sometimes question the effectiveness of an oxygen-barrier in reducing the rate of color change.

Two studies were performed by the University of Vermont Proctor Maple Research Center in 2018 and 2019 to compare the rate of color (LT) change in maple syrup in uncoated and XL-coated retail plastic containers.

Methods

In the first study (2018), several quart or liter samples of maple syrup packed in both uncoated and XL-coated were supplied by three different packers: Citadelle (Québec, Canada), LB Maple Treat (Québec, Canada), and Bascom Maple Farm (New Hampshire, U.S.A.).

For two of the packers, samples were packed back-to-back on the same day. For the third, syrup was packed on two sequential days (separated by the weekend).

Samples were shipped and took up to two weeks to reach UVM PMRC, so there was no way to independently assess darkening for the immediate time period after packing. The LT at the time of packing was supplied by each packer.

For the second study (2019), four companies supplied syrup samples, the three noted above and Butternut Mountain Farm (Vermont).

In addition, syrup from UVM PMRC was packed into uncoated or XL-coated containers. This resulted in a total of 5 sites supplying sample syrup.

In this case, we observed the maple syrup as it was packed at each site in uncoated and XL-coated containers on the day of packing and obtained a syrup sample.

The LT of the sample of syrup being packed was tested within 1 hour of packing.

The remaining samples were then shipped (from Canada) or transported immediately to UVM PMRC by automobile (from New Hampshire and Vermont) immediately after packing.

All samples for both studies were stored in the dark at room temperature (70°F) until measurements were made. At approximately monthly intervals, the LT of three duplicate samples from previously unopened containers of syrup from each site for both uncoated and XL-coated containers was measured using a calibrated Hannah HI759 Digital Maple Syrup Grader (Hannah Industries, Smithfield, RI, U.S.A., + 4% accuracy).

Three duplicate readings were taken from each syrup sample and the average recorded. For both study 1 and 2, the packing companies provided the measurement of the LT of the syrup when packed.

In addition, for study 2, the single sample measured within 1 hr of packing was used to provide a baseline LT. Measurements continued at approximately monthly intervals for the next 6-7 months for both studies.

Results

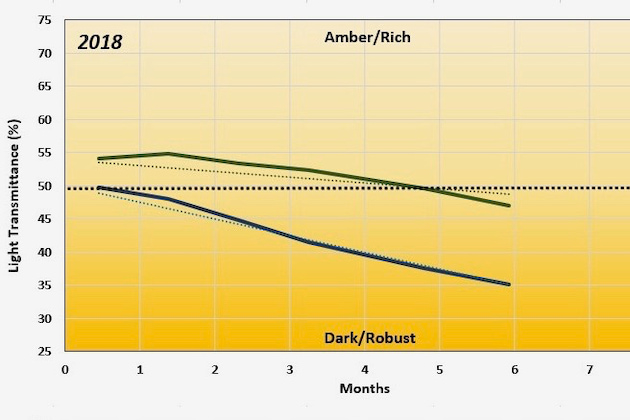

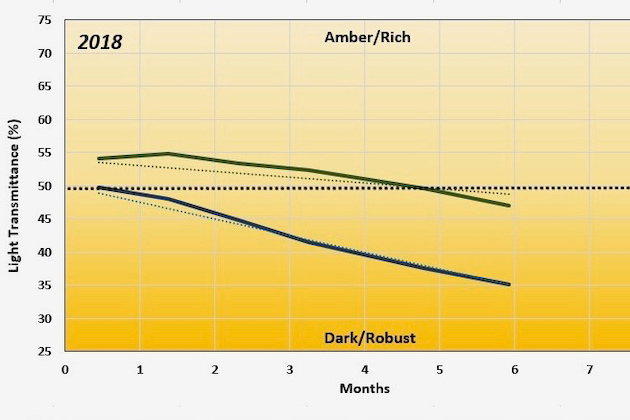

The maple syrup packed in the course of the two studies showed very similar trends in LT (Figure 1).

Darkening of maple syrup occurred in a near-linear fashion (r² values were within the range of 0.75-0.95 and significant to p < 0.05) in both container types for each year, however the syrup LT in XL-coated containers lost LT at a significantly slower rate (average 0.8% loss in LT per month) than in uncoated containers (average 2.6% loss in LT per month).

Thus the darkening rate in uncoated containers averaged 3.3 times the rate of darkening in XL-containers. Although there were slight variations from month-to-month and site-to-site, these tended to even out over the course of each study, and the overall trends observed in the rate of darkening were similar within the main comparison of uncoated versus XL-coated containers.

Over the six month course of these two studies, syrup packed in XL-coated containers dropped an average of less than 5% in LT, demonstrating that the XL coating substantially retarded oxygen permeation and loss of LT.

Syrup packed in uncoated plastic containers on the other hand dropped an average of 15.5% over the same time period. Clearly the XL-coating is very effective in retarding the rate of darkening in maple syrup packed in plastic containers.

Functionally what this means is that maple syrup packed in uncoated containers will suffer a far more rapid loss in LT after packing (during shipping and on the retail shelf) and is considerably more likely to fall out of color-grade unless sold and consumed relatively quickly.

In the 2018 study, much of the syrup packed in uncoated containers had already lost a grade prior to the first sample period. In 2019 the syrup in uncoated containers was at the dividing line between Amber/Rich and Dark/Robust within 2 months.

In contrast, syrup in XL-coated containers retained the same grade for nearly 5 months and for over 7 months in 2018 and 2019 respectively.

Although a short residence time between when syrup is packed and sold would likely be satisfactory for uncoated containers, XL-coated containers are a better choice when more than a few months elapses between packing and sale, if producers/packers wish to ensure better stability of the syrup grade, or if producers/packers wish to pack relatively close to the dividing line of two grades.

Acknowledgements

We are grateful to Citadelle Maple Products, LB Maple Treat, Bascom Maple Farms, and Butternut Mountain Farms for their cooperation in this project and for supplying the syrup used in this study.

We also thank Plastic Industries (Sugarhill) for financial support, supplying the plastic containers, and helping to schedule and coordinate the site visits to packers and shipping of the syrup in both years.

Dr. Abby van den Berg (UVM) provided useful advice and comments throughout this work.