Sap & Syrup

Bulk market flat this summer

Northeast’s biggest syrup buyer expands facility

By PETER GREGG | NOVEMBER 21, 2018

ALSTEAD, N.H.—The bulk market is holding its own this fall, with little changed from the spring other than there is more syrup out there than predicted.

“I think the crop is at least as big as last year’s,” said Bruce Bascom of Bascom Maple Farms, one of the biggest on-site bulk buyers in the Northeast.

Bascom said syrup coming out of the field has continued to show up at his warehouse door throughout the summer and early fall.

“We’ve been getting five pick-up loads per day five days per week,” Bascom said last month.

The general bulk price has remained unchanged since the spring.

Bascom said he is paying $2.10 per pound for Golden Delicate, $2.00 per pound for Amber and Dark and $1.75 for very dark.

Processing grades are only fetching $1.10 and generally Bascom says he doesn’t want it.

“People are making too much processing syrup,” he said.

On the consumer end of the market, things slowed over the summer.

“Sales were flat,” Bascom said.

He and his chief retail marketer Arnold Coombs said the hot summer across the U.S. was to blame.

“People don’t eat as much syrup when it’s hot,” Bascom said.

Bascom said he is still taking in syrup but his holding tanks are largely full.

“I have enough syrup right now to get to next July,” he said.

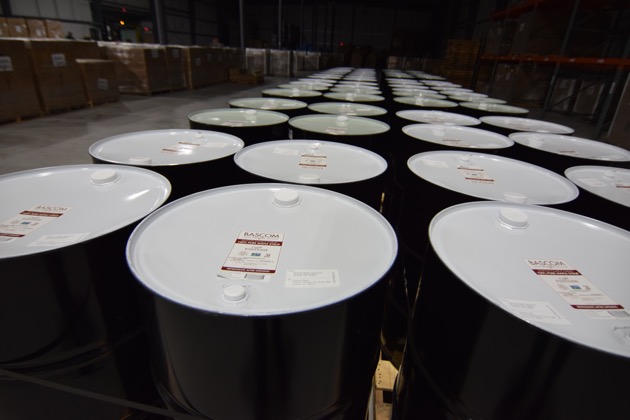

Meanwhile, Bascom has been expanding his facility.

This summer a new $500,000 packing line was added to handle quicker fill production of 8oz. and 12oz. glass bottles.

And work has been largely completed on a massive multi-million warehouse toward the back of the Bascom campus.

Bascom and Coombs predicted that the annual growth rate has dropped to about 5 percent per year, down from 10 percent annual growth predictions.

Still the market is moving syrup.

“I wouldn’t be buying it if it wasn’t turning over,” Bascom said.