Vacuum & RO

Bosworth Co. introduces new pump and diaphragm

The new

By PETER GREGG | OCTOBER 4, 2023

EAST PROVIDENCE, R.I.—The Bosworth Company is on a roll.

The company has become famous in the maple industry for their diaphragm pumps, which they market under the “Guzzler” brand name.

The pumps are economical and can pull upwards of 28 or even 29 inches of mercury vacuum if sugarmakers are vigilant about checking leaks and keeping the valves wet.

“All of our Guzzler pumps would qualify as high vacuum pumps,” said Douglas L. Reilly, President & CEO, during an interview with The Maple News.

Now this fall the company has two big new announcements.

They are introducing a new pump called the “Quad” which will house four diaphragms and is rated to work for sugarbushes of up to 1800 taps.

The company says the pump will sell for less than $3,000, getting a sugarmaker into high vacuum at an economical price without the need or hassle of a releaser.

Four of the Quad pumps were test marketed by sugarmakers in the field last season with great results, the company said.

Sugarmaker Brandon Daniels in Dawson, W.V. added a Quad pump last season on a bush of 900 taps on 3/16ths lines.

"It increased our production by 30 to 40 percent over our six-year average," Daniels said. "It did a good job."

The Quad pump will be demonstrated at the North American Maple Syrup Council annual meeting in Sturbridge, Mass. in October and other shows this fall and winter.

The Quad pump will have a ¼ horse motor and will only draw 3 amps and 120 volts, so it can run off a battery in a pinch, or even solar.

The other big announcement from Bosworth is regarding the diaphragms themselves.

Bosworth has developed and will be mass producing new diaphragms made from a rubber material that will hold up and maintain through an entire sugaring season.

On a single diaphragm.

The new diaphragms are made from an FDA-approved food-grade material called Santoprene.

“This will last through a whole season,” Reilly said.

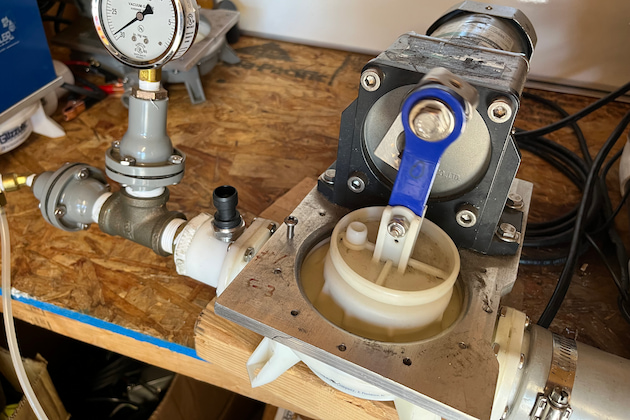

In fact, in the company’s “test shed” in the back of their factory, Reilly and his production team have been running a Guzzler pump on one single Santoprene diaphragm continuously since December of 2022.

“It’s still going,” Reilly said, during a tour for The Maple News in August.

He still recommends that the sugarmaker still make an effort to keep ice out of the pumps, primarily by using a screen.

Meanwhile, the catalog of Guzzler pumps, and the corresponding “Sap Check” monitoring systems continue to be a hit with small scale producers.

Bosworth Company pumps and equipment are manufactured by hand by seasoned, experienced employees in the company factory in East Providence, R.I.

The Guzzler single diaphragm pumps are reliable workhorses for many small sugarmakers and are rated for up to 400 taps.

The company’s double-diaphragm “Sap Puller” model is rated up to 900 taps.

Sugarmakers are encouraged to check for leaks often when using any pump, to achieve the highest possible vacuum. (High vacuum is thought to be any vacuum level higher than 25hg).

Reilly said all the Guzzler high voltage pumps can achieve 28 or even 29 inches of mercury vacuum, but not without a little help from the sugarmaker (the lower 24-volt machines can get a maximum of 25 inches, he said.)

The best way to achieve this is by making sure all lines are completely leak free, and by making sure the valves are wet.

“Wet valves seal,” he said.

Reilly said a lot of sugarmakers use a separate line to continually cycle water into the pump to keep the valve and diaphragm wet, helping to ensure that high vacuum level.

If the valves are dry, the machines can only get 19 or 20 inches.

The pumps have low C.F.M. so they are less forgiving of leaks.

“If you got a leak, more air come into the line faster than the pump can pull it out,” Reilly explained.