Cornell Corner

3/16” tubing results from Uihlein Forest

Skepticism remains among producers reluctant to switch

By MICHAEL FARRELL | FEBRUARY 2017

There has been a lot of interest in 3/16” tubing systems over the past several years. Tim Wilmot’s research on this novel concept has caused a lot of producers to rethink how they install new tubing systems or potentially renovate their existing sugarbushes. Despite a lot of in-depth research reports and successful stories from sugarmakers who have used 3/16” systems, there still remains a lot of skepticism and questions among producers who are reluctant to switch away from 5/16” systems. It should be obvious that using 3/16” will always be better in a gravity based system, yet the answer when using vacuum pumps does not have a solid consensus. In 2016, we received funding from the Northern NY Agricultural Development Program to conduct research and extension on using 3/16” tubing systems under vacuum. This article describes our research results from the past year and outlines future directions.

At the Uihlein Forest in Lake Placid, we installed twelve 30-gallon canisters within our existing sugarbush. These were strategically placed near the end of mainlines to be able to have between 17-33 taps flow in to the canister. Six of the canisters had two 3/16 lines going in to it with an average of 8.5 to 13 taps per lateral line. The other six canisters had 1” mainlines with regular 5/16” tubing and an average of ~3 taps per lateral line. Table 1 contains information on the total number of taps for each canister, as indicated by the mainline that it is connected to.

A picture of one of the 3/16 canisters is seen in Figure 1. The canisters were custom made by Lapierre to be able to be placed in an existing tubing system, measure sap volume, and then release the sap in to the mainline without ever interrupting vacuum to the tapholes. The regular mainline goes to the bottom of the canister and a “dryline” tees off the mainline to go to the top of the canister. We normally have the valve shut on the bottom of the canister to allow sap to collect in the canister; the vacuum is supplied at the top of the canister via the “dryline”. There is a Tee at the bottom of the canister that allows us to let the sap flow in to a graduated cylinder on the side of the canister and measure the volume before we open the valve to let it flow down the mainline. Once all the sap is measured and emptied, we close the valves and let it fill up again.

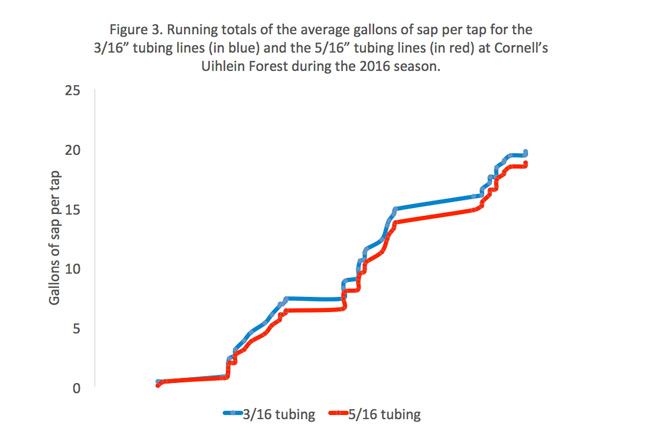

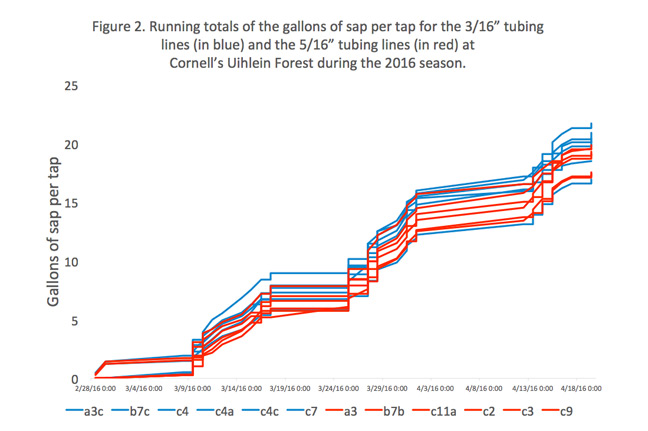

Though it is generally not advisable to make any conclusions based on one year of data, in the interest of getting the initial results to producers and meeting reporting requirements for NNY Agricultural Development Program (who funded this project), we have decided to release the initial results now. The results of the first year can be found in Figures 2 and 3. Figure 2 presents the running total of gallons of sap per tap for each canister whereas Figure 3 is the average for all of the 3/16” vs. all of the 5/16” tubing systems. While there is some expected variation among the different tubing lines, the 3/16” tubing systems provided an average of 19.5 gallons of sap per taphole whereas the 5/16” lines produced 18.5 gallons of sap per tap. It’s worth noting that this is not statistically significant, meaning that the difference could be due to chance rather than something that would cause inherent differences in how the systems perform.

Although the average yields between the 3/16” and 5/16” tubing systems were not statistically significant, it is worth noting that the top four producing lines were all 3/16” systems. We did have two 3/16” systems that did not fair so well (thus bringing down our average), but there may be explanations for these discrepancies. The lowest yielding 3/16” systems were found on lines with less ideal conditions for sap flow. In fact, our worst line was at the very top of the sugarbush where we have more significant dieback issues. Thus, the lower sap yield may have been due more to tree health than the type of tubing. Our second worst performing 3/16 line was in an area of the sugarbush that is more of a flat plateau and had only a few feet of elevation gain within the collection area. This area would not be considered an ideal area for 3/16” tubing, but we put one there anyways just to have at least one area with 3/16” on relatively flat ground.

In 2016, all of the 3/16 and 5/16 tubing was brand new. One of the concerns with 3/16 tubing is how it holds up over time. We will continue to measure and monitor sap volumes for several years to determine how yields change as the systems become more contaminated. We will simply use the “dry clean” method of pulling taps under vacuum, as that seems to be the most commonly used cleaning method in the maple industry today. If the 3/16” becomes more contaminated and plugs up, that will become evident in the years ahead. Being able to continue to measure sap volume over time will be an important step towards determining if using 3/16” tubing under vacuum is an advisable recommendation. Unfortunately, it is too early to tell at this point since the technology is so new.

Although the results from the research at the Uihlein Forest cannot be used to providing concluding evidence, it is worth noting how we are already using the information gathered in our own experiments and those completed by other researchers. Although I am concerned that 3/16” tubing could experience difficulties over time, at this stage the benefits of installing 3/16” tubing are so great (lower installation costs and potentially higher vacuum) that we will likely be switching out the majority of our 5,500 tap tubing system to 3/16” in the next year. This is a decision that I will leave to the next Director, but my recommendations are to switch out two of our systems (80% of the taps) and leave one system as a control. After all, we rely on syrup income as a main part of our budget and strive to make the most we possibly can while conducting applied research. The tubing system is mostly over 10 years old now and the lateral lines should be replaced, so we will be doing 3/16” on a much larger scale in the years ahead.

A separate but related part of our research involved measuring the difference in vacuum levels when using 5/16” droplines vs. 3/16” droplines in a typical vacuum-enhanced tubing system. We were able to obtain some 5/16” x 5/16” x 3/16” Tees and collaborated with Paul Smiths College to install them in their sugarbush. The vacuum levels generally hovered close to 20”, so there was definitely room for improvement in bringing additional vacuum to the taphole. We simply put one regular 5/16” Tee with a vacuum gauge at the same height of the taphole and located that right next to a 3/16” dropline that also has a Tee within it for a vacuum gauge. Thus, the vacuum levels were being measured directly next to each other, at the same height. The only difference is that one was using 5/16” tubing and the other 3/16” tubing. Most of the droplines were 36” but we also experimented with some longer ones (up to 72”). An example of this can be seen in Figure 4.

In all circumstances, the vacuum levels on the 3/16” droplines were significantly higher than the 5/16” lines. That is the incredible thing about 3/16” tubing- the vacuum within in a line can be enhanced by only a few feet of additional vertical drop created in the dropline. The theoretical maximum vacuum enhancement is .88” for every foot of elevation gain, and the taller the dropline, the greater the enhancement. Thus, simply replacing droplines in an existing 5/16” tubing system with 5/16” x 5/16” x 3/16” Tees may result in significant increases in yield. You will gain the benefits of a new dropline as well as enhanced vacuum from the vertical fall through 3/16” tubing. The older your droplines, and the lower your vacuum level is to begin with, the greater the benefit will be. If you are already achieving 27” or more of vacuum throughout your sugarbush, then there is no need to change anything!

Our future plans at the Uihlein Forest include replacing the droplines in the 5/16” tubing system that will not receive new 3/16” laterals. It is cheaper and easier to simply replace droplines than an entire tubing system, so we will also do that and monitor the yields over time. If you aren’t ready to make the jump to entirely renovating your tubing system with 3/16”, you may try just switching out your droplines by using 5/16” x 5/16” x 3/16” Tees.