Sugarmaker Profiles

750,000 taps to start ...

'Nothing to fear,’ exec says of world’s largest maple operation

By PETER GREGG |

ISLAND POND, Vt. — The nation’s biggest maple operation plans to have 200,000 taps or more in for this season and has already made syrup this month, getting a jump on the season.

“We’ve had some very good runs,” said Joe Russo, a longtime Vermont sugarmaker who has signed on as chief operating officer for Sweet Tree Holdings LLC in Island Pond, Vt. in the Northeast Kingdom region of the state. “We’ve made beautiful syrup.”

Russo said tapping is done and the company landed at 200,000 for the season — its second.

The company plans to eventually plug in more than 750,000 taps, according to company officials. But they continue to insist they have no plans to glut the market with syrup.

“People have nothing to fear,” Russo said during an interview with The Maple News last year. “Nobody is trying to destroy the market. In fact people will be thanking us for bringing Vermont maple to the market on such a wide scale.”

Company officials at Sweet Tree, a subsidiary of Connecticut-based Wood Creek Capital Management, a $2 billion hedge fund which most notably owns music publishing rights to “Bust A Move,” “Come On Get Happy” and the song catalog of Kenny G, claim they will put very little syrup on the market.

Instead the company plans to market “alternative, value-added products” but has still resisted calls to disclose what those products will be. Rumors abound that teas, distilled liquors and other speciality items are in development at the Island Pond facility.

“No one is doing these products either nationally or internationally,” said Mike Argyelan, chief financial officer of the company. “Things have been made similar but not on the scale we envision.”

The Sweet Tree project has been the talk of the maple industry for more than two years. The Maple News was given a tour of the operation last summer and it was a featured stop on the Vermont Maplerama tour in July.

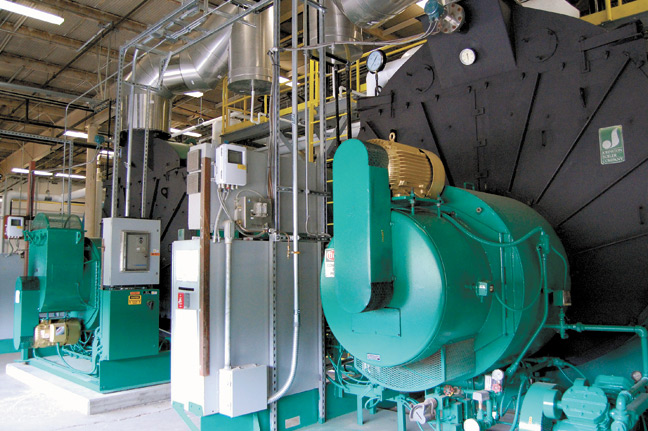

Last year the company installed 93,500 taps in time for the 2015 sugaring season and equipped the 90,000 square foot former Ethan Allen furniture plant in Island Pond with four massive steam boilers.

In the woods, more than 1,700 miles of tubing have already been installed by a crew of more than 30 men and another 6,000 miles will be going in.

“We have enough tubing to go from here to California and back,” Argyelan said.

And from there the company expects to go even bigger.

“We hope to be somewhere at 750,000 taps to start,” Argyelan said. “We have the capacity and the wherewithal to greatly increase that number or purchase outside syrup that meets our standards.”

Twelve miles up the road from the main plant, in Norton, Vt. is the company’s main sugarbushes, where an army of installers have worked around the clock to get the tubing strung up in two main areas that are either owned by the company or leased.

CDL USA and the Chabot family have the contract on the installation and materials and Sweet Tree officials have had much praise for the equipment company.

“They have been absolutely wonderful to work with,” said Russo about his partnership with CDL. “Everything has been professionally engineered and thought out.”

Russo, who owns his own 70,000-tap operation in nearby Belvedere, Vt. set up the massive boiling room in the former Ethan Allen plant. Twenty-four percent concentrate is pumped into four steam-heated evaporators, only two of which were used last season.

The system is so efficient that Russo said he made one 55 gallon drum of syrup in one minute and 45 seconds.

The company viewed the 2015 season as a “test year,” Argyelan said.

“We wanted to get the bugs out,” he said.

Original: June 2015

Updated: February 2016